Published: 2025-07-29 Last Updated: 2025-07-29

Background

As the global lithium battery separator market grows rapidly—projected to reach $18.34 billion by 2030—ceramic-coated separators are becoming the industry standard. These materials demand cleaner, more stable slurry transfer systems. Traditional rotary pumps struggle with high-viscosity ceramic slurry, often causing metal contamination, leakage, and frequent maintenance.

This case study shows how the GRACO QUANTM electric diaphragm pump delivers clean, low-pulsation, leak-free transfer—solving key pain points in modern lithium battery manufacturing.

What Is Ceramic Slurry for Lithium Batteries?

Ceramic slurry is a high-viscosity mixture used for coating lithium battery separators. It typically contains fine inorganic particles such as alumina (Al₂O₃) or silica (SiO₂), blended with organic solvents and dispersing agents. This ceramic coating significantly enhances the separator’s thermal stability, puncture resistance, and overall safety.

Due to its thick consistency and high solid content, ceramic slurry poses serious challenges for fluid transfer. It demands extremely clean and sealed systems, and its abrasive nature can cause wear on pumps and pipelines—making equipment durability and contamination control critical for battery manufacturers.

📌 On-Site Ceramic Slurry Transfer: How to Eliminate Leaks and Minimize Metal Contamination

Case – Housheng Technology (Jiangsu & Shanxi), Supplier of Lithium Battery Materials

CURRENT STATE

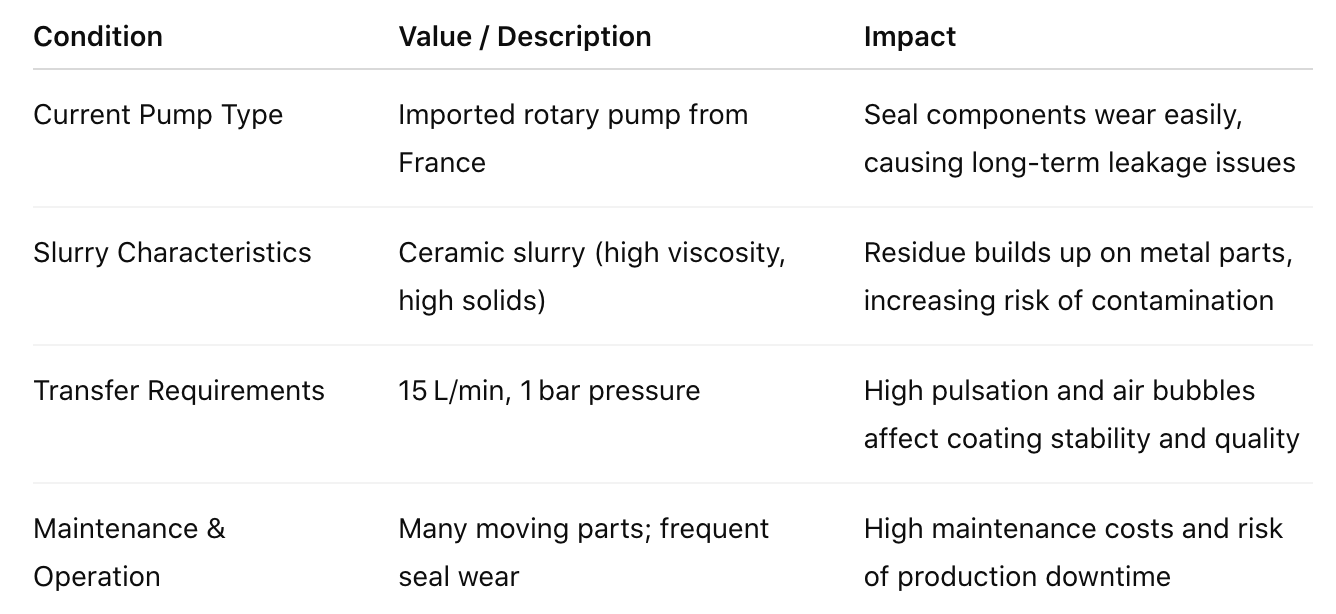

Housheng Technology, based in Jiangsu and Shanxi, supplies raw materials for lithium batteries.

Their production line requires stable transfer of high-viscosity, high-solid ceramic slurry at 15 L/min, under 1 bar pressure.

Since the slurry is sensitive to bubbles, pulsation, and metal contamination, they needed a pump with high sealing, low pulsation, corrosion resistance, and easy cleaning—to ensure clean and stable operation.

Improvement Goals

- 1. Eliminate leakage caused by rotor pump seal wear

- 2. Prevent contamination from slurry contact with metal moving parts

- 3. Ensure stable transfer of high-viscosity, high-solid-content slurry

- 4. Reduce air bubbles and pulsation to improve coating quality

💡 Say Goodbye to Leaks and Metal Contamination — QUANTM Electric Diaphragm Pump Solves 4 Major Challenges with Ease

The original rotary pump had frequent seal wear, leading to leaks and metal contamination that affected coating quality. By switching to the GRACO QUANTM i30 (PP), the plant eliminated metal contact and improved reliability. Its diaphragm design enables smooth, low-pulsation transfer of high-viscosity slurry—compact, clean, and easy to maintain.

🔧 How Does the Electric Diaphragm Pump Meet Customer Requirements?

| Goal |

QUANTM Solution |

| 🎯 Eliminate leakage caused by seal wear in rotary pumps |

✔ Designed with a seal-free, electrically driven mechanism—no lubrication or seals required—ensuring leak-free operation and a cleaner, safer environment. |

| 🎯 Prevent contamination from ceramic slurry contacting metal moving parts |

✔ Fluid-contact components are made entirely of non-metallic materials (PP), with no metal moving parts—minimizing contamination risks and ensuring slurry purity. |

| 🎯 Ensure stable transfer of high-solid, high-viscosity ceramic slurry |

✔ Diaphragm pump structure is optimized for thick and solid-loaded fluids, offering self-priming capability and consistent flow—ideal for challenging slurries. |

| 🎯 Reduce air bubbles and pulsation to improve coating quality |

✔ Fine-tuning of the outlet valve suppresses pulsation and flow fluctuation, enabling smooth delivery and improving coating uniformity and yield. |