Published: 2025-07-07 Last Updated: 2025-07-07

Background

HDI and substrate demand are surging, making nozzle precision a key to PCB yield. According to Precedence Research's 2024 market report, the global PCB market has reached USD 91.8 billion and is projected to climb to USD 152.5 billion by 2033, with a compound annual growth rate of approximately 5.8%. As HDI and substrate technology continue to shrink, line width and spacing (L/S) are rapidly compressing from 40/40 μm to 25/25 μm, even pushing the limits towards 15/15 μm. With the process window shrinking to its limit, the spray uniformity of the DES section directly determines etching factors and fine-line yield. Once spray distribution becomes uneven or pooling occurs, how to maintain high uniformity at low flow rates, reduce maintenance downtime, and improve chemical utilization has become a top priority for production lines.

What is a PCB DES Spray System?

DES (Developing-Etching-Stripping) equipment uses high-pressure nozzles to evenly spray developer, etchant, and stripper onto the copper surface. The goal is to remove the photoresist in the shortest possible time, stabilize the etching rate, and control undercut to ensure consistent line width and spacing (L/S). Uneven spray distribution or spray dead zones can cause liquid accumulation, forming "pooling" effects, which directly increase ΔTh (copper thickness variation) and worsen etching uniformity.

📌 PCB DES System: How to Improve Spray Uniformity, Eliminate Pooling, and Stabilize Etching Quality?

Actual Case - Fine-Line Production Line of a Major PCB Manufacturer

Current State

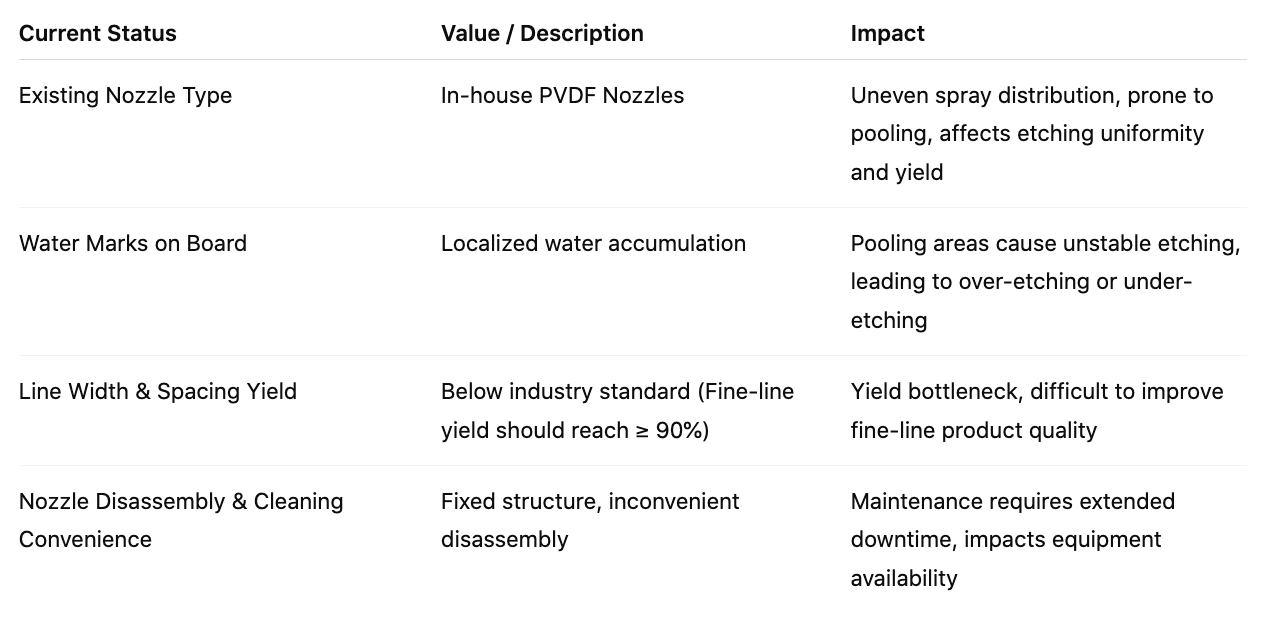

This production line has long been dedicated to manufacturing high-density, fine-line multilayer PCBs, where etching uniformity is critical. The original equipment used in-house PVDF nozzles, which provided basic water flow, but as circuit designs became finer, the following issues gradually emerged. The production manager hopes to enhance nozzle structure and spray performance to significantly improve water flow uniformity, reduce defects, ensure product consistency, and simplify equipment maintenance.

Improvement Goals

- 1. Completely improve water flow uniformity and eliminate pooling

2. Optimize etching factor distribution to enhance line width and spacing stability

3. Break through 90% yield and reduce product quality variation

4. Quick-release design to reduce cleaning and maintenance time

💡 Eliminate Pooling, Etching Instability, and Yield Bottlenecks — LORRIC Quick-Release Nozzles Solve Five Key Challenges at Once

By introducing LORRIC QFMF quick-release nozzles to PCB DES equipment, this project eliminated pooling and uneven etching. The multi-slotted core and curved outlet ensure uniform spray, improving etching stability and pushing fine-line yield beyond 90%. The quick-release design reduces maintenance time, while customized angles and flow rates optimize spray performance and overall process stability.

🔧 How Do LORRIC-Engineered Nozzles Meet Customer Needs?

Goals vs. Solutions

| Goal |

QUANTM Solution |

| 🎯 Improve Spray Uniformity and Eliminate Pooling |

✔ QFMF nozzles feature a multi-slotted core that generates multiple rotating liquid streams. These streams pass through a curved outlet and are ejected by centrifugal force, creating a stable, uniform circular spray that eliminates pooling. |

| 🎯 Enhance Etching Factor Stability |

✔ Excellent turbulence control ensures uniform flow distribution and spray particle size, providing consistent chemical coverage, reducing over-etching or under-etching, and improving overall etching stability. |

| 🎯 Exceed 90% Fine-Line Yield |

✔ Flow tolerance controlled within ±5% and spray angle within ±5°; uniform spray coverage significantly boosts fine-line yield. |

| 🎯 Quick-Release Design Reduces Maintenance Time |

✔ Two-piece quick-release design with precise locking mechanism allows tool-free installation and removal, prevents leakage, and greatly reduces cleaning and maintenance time. |