Published: 2025-06-06 Last Updated: 2025-06-10

Background

According to a May 2025 report by Precedence Research, the global semiconductor wet process chemicals market will be worth approximately $14.9 billion in 2024; and analysis by Maximize Market Research and TECHCET shows that the market will continue to expand at a compound annual growth rate of 6-7% in the future, driven by the increase in the number of advanced process layers and investment in new wafer fabs.

As wafer fabs continue to demand "precise, stable, and zero-pollution" chemical delivery, system integrators need low-noise, remotely monitored, and small-footprint pump solutions to ensure 24/7 continuous operation and clean room environment compliance with regulations. This article will introduce the pain point solutions and practical application results of GRACO electric diaphragm pumps in semiconductor CDS systems.

What is CDS?

CDS stands for Chemical Dispensing System, which is a chemical supply system. This system is generally installed at the "supply end" of the semiconductor process and is responsible for transporting chemicals from the storage tank to process equipment such as etching machines and cleaning machines through pumps, pipes, valves and other components. The CDS system can be customized according to the properties and flow requirements of different chemicals to achieve very precise liquid delivery.

📌 Tackling Key Challenges in Semiconductor Chemical Delivery: Noise, Air, Space, and Remote Control

Actual Case Customer-LTCAM Semiconductor Chemical Delivery System Integrator

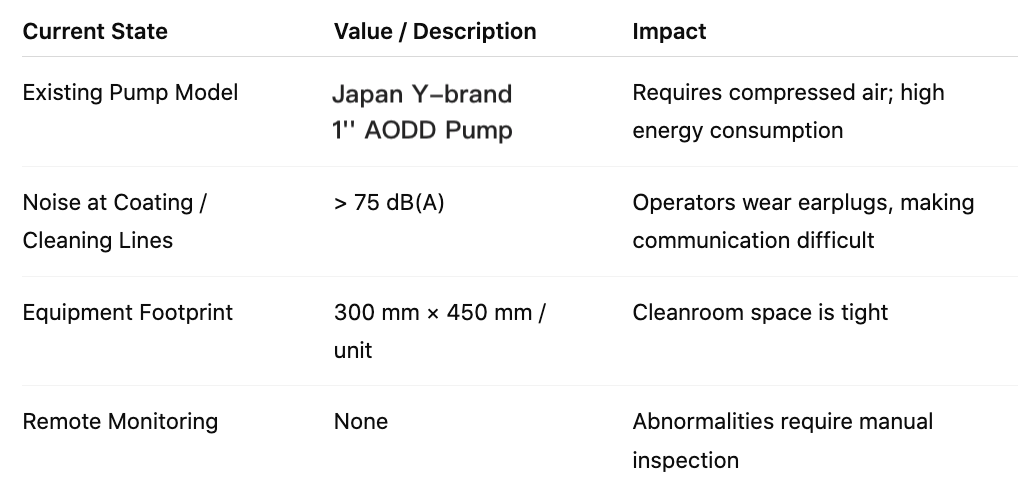

Current State

LTCAM is a specialized integrator of semiconductor chemical delivery systems. In the clean room chemical supply area of the plant, pipelines need to continuously deliver a variety of high-purity chemical fluids, including wafer cleaning fluid, etching fluid, CMP polishing fluid and electroplating fluid. These fluids are highly corrosive, with different viscosities and specific gravities, and must be supplied to process equipment at a stable flow rate in a closed pipeline all day long.

Improvement Goals

- 1. Reduce operational noise

- 2. Avoid increasing system footprint

- 3. Eliminate compressed air piping to reduce energy use and maintenance

- 4. Integrate pumps with PLC for automated monitoring

- 5. Replacement pump must support dry-run and self-priming functions

💡 Solving the Top 5 Issues in Chemical Delivery with the QUANTM Electric Pump

In this case, a 1-inch air-operated diaphragm pump was replaced with the GRACO QUANTM i30 electric double diaphragm pump.

The electric motor eliminates the need for compressed air, reducing noise while cutting energy and maintenance costs.

Its compact size fits the original frame with no extra footprint. Core features like self-priming and dry-run capability are preserved, ensuring safe shutdown, drainage, and CIP operations.

With a built-in Modbus-RTU interface, the pump connects directly to the PLC, enabling real-time monitoring and seamless automation.

📊 Proven Results: 71% Energy Savings and 14 dB Noise Reduction

Goals vs. Solutions

| Goal |

QUANTM Solution |

| 🎯 Reduce operating noise and improve the working environment |

✔ Driven by a brushless motor, it runs smoothly and quietly. Noise reduced from 75 dB to 61 dB, vibration < 0.3 mm/s. No PPE required; can be installed on the same equipment frame. |

| 🎯 Maintain existing pipeline configuration without increasing floor space |

✔ The pump body measures only 250 × 310 mm — 42% smaller than the old model. Fits original frame directly with zero footprint growth. Cleanroom cleaning becomes easier. |

| 🎯 No longer rely on compressed air, reducing energy consumption and maintenance |

✔ Electric motors replace air compressors, eliminating air source dependency. 16 pumps save 30 MWh annually and reduce air equipment maintenance costs. |

| 🎯 Automatically monitor pump status via PLC |

✔ Built-in I/O and Modbus-RTU support enable direct PLC integration. Real-time feedback to SCADA for start/stop, flow, and pressure monitoring. |

| 🎯 Maintain dry-running and self-priming characteristics for shutdown or CIP operations |

✔ Supports 6-meter self-priming height, dry-run for 30 minutes. Can restart after shutdown without pre-filling — safe for CIP and drainage. |