1. What is Accuracy

In industrial process control, energy management, and quality control, measurement accuracy refers to the degree of closeness between the measured value and the true value. It is commonly expressed as a percentage of allowable error, such as "±1%," meaning the actual measurement result will fall within 1% above or below the true value.

When discussing accuracy, there is a fundamental concept to keep in mind: no matter how advanced the equipment is, minor errors or variations are inevitable.

Imagine if we demanded that every product must be completely error-free and match the design value 100%, the results would be:

• Almost every product would be classified as defective

• Production efficiency would significantly decrease

• Costs would increase dramatically, resulting in waste

Therefore, during product design and inspection, an "acceptable tolerance range" is usually defined. As long as the product falls within this range, it is considered qualified, capable of functioning properly, and not affecting overall quality. This range is known as tolerance.

2. Difference Between Measurement Accuracy and Repeatability

In the specifications of flowmeters or other measurement instruments, you may often come across the term "repeatability."

Repeatability and the measurement "accuracy mentioned" earlier are two completely different concepts.

|

Repeatability |

Measurement Accuracy |

| Definition |

The consistency or closeness of measurement results when the same quantity is measured multiple times under the same conditions. Repeatability reflects the short-term stability of the measuring instrument or system. |

The degree of closeness between the measured value and the true value (or reference standard). Measurement accuracy reflects the correctness of the measuring instrument. |

| Example (Flowmeter) |

Suppose you use a flowmeter to measure the same flow rate (e.g., 10 liters per second) and repeat the measurement 10 times under the same conditions. If the flowmeter has high repeatability, the 10 results will be very close, such as 9.98, 9.99, or 10.01 liters, etc. The higher the repeatability, the smaller the data dispersion. |

If you want to measure a liquid flow rate of 10 liters per second, ideally, the flowmeter should display exactly 10.0 liters per second. If it shows 9.8 liters per second, the measurement accuracy is relatively low. The higher the measurement accuracy, the closer the reading is to the true value of 10.0 liters per second. |

Simply put, good measurement accuracy does not guarantee stable results, and good repeatability does not necessarily mean the measurement is accurate. Only when both accuracy and repeatability are achieved, along with proper calibration, can a measuring device be truly reliable.

When selecting a flowmeter, accuracy is important, but generally, the higher the accuracy, the higher the price. It is recommended to find a balance between accuracy and cost based on your actual needs. For example, if you only need to know the approximate amount of tap water in a pipeline, a high-accuracy water flowmeter is not necessary. However, for chemical liquid monitoring in precise manufacturing processes, higher flowmeter accuracy is required.

3. Accuracy Indication Methods: Full Scale (%FS) vs. Reading Value (%Rd)

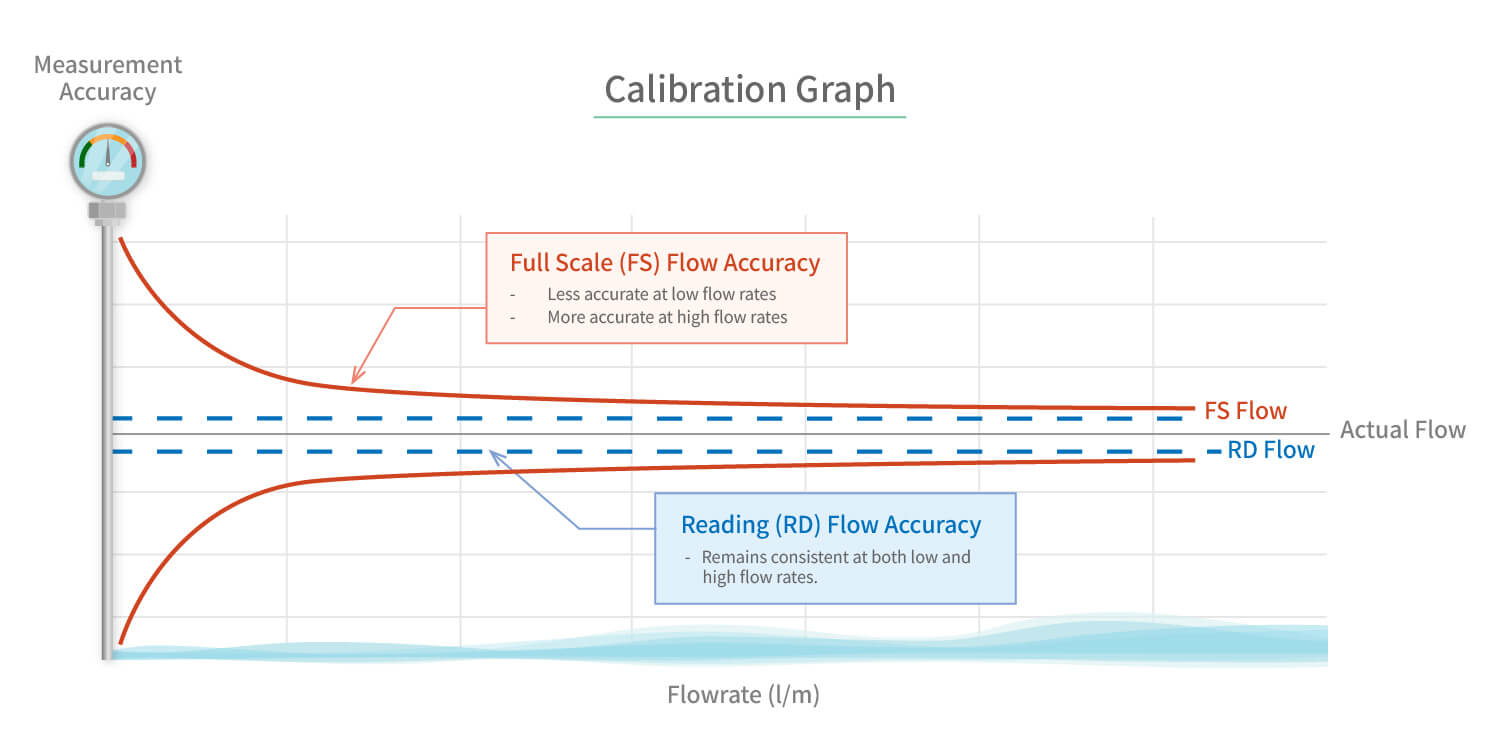

There are two common ways to indicate accuracy: Full Scale percentage (FS) and Reading percentage (Rd or RD).

1 ) What is Full Scale Accuracy (%FS)?

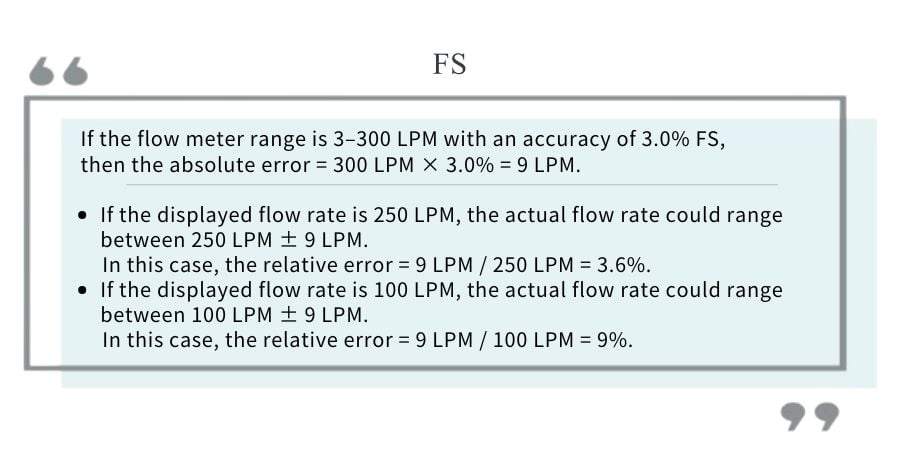

When using Full Scale (FS) to express accuracy, the error is calculated based on the maximum measurement range. The absolute error remains constant, but the relative error, expressed as a percentage of the actual flow rate, changes as the flow rate varies.

The advantage of using Full Scale (FS) to express error is that it is simple and easy to calculate, as the absolute error is based on the full-scale value and remains constant. However, when the flow rate decreases, the absolute error accounts for a larger percentage of the actual flow rate (relative error), resulting in reduced measurement accuracy.

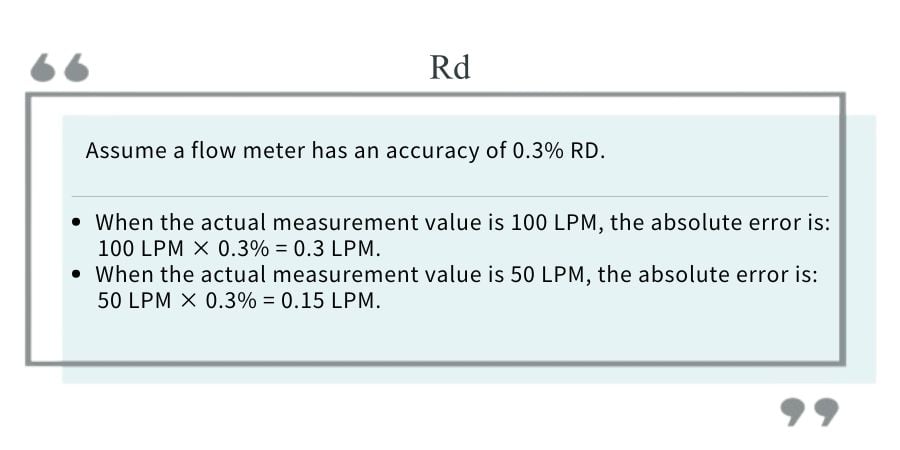

2 ) What is Reading Accuracy (%Rd)?

When using Reading (abbreviated as Rd or RD) to express accuracy, the error is calculated based on the actual measured value. Regardless of where the flow rate falls within the measurement range, the percentage is always calculated based on the current reading.

The advantage of using Reading (RD) to express accuracy is that the error varies with the measured value, providing more precise and stable relative error for low flow measurements. This makes it suitable for applications with fluctuating flow rates, as it helps maintain accuracy across a wide range. However, the drawback is that the calculation is more complex, requiring dynamic calculation for each reading. In addition, at high flow rates, the error may increase, which can affect measurement accuracy under high-flow conditions.

4. Commonly Confused Concepts: Linearity vs Accuracy

Linearity, sometimes referred to as straightness, is used to evaluate how closely a device's measurement results match the theoretical straight line (ideal input-output relationship). If the output trend follows a straight line as the input changes, it indicates good linearity.

Accuracy emphasizes how close the measurement result is to the true value. The difference between the two is that accuracy focuses on the correctness of individual results, while linearity focuses on the stability and predictability of the overall output trend.

What is the difference between linearity and repeatability?

Repeatability refers to the consistency of multiple measurement results under the same conditions, focusing on how close the results are to each other. Linearity observes whether the output trend follows a regular pattern (close to the theoretical straight line) as the input changes.

For example, if the repeatability is ±0.1% FS, it means the maximum deviation of repeated measurements under the same flow conditions does not exceed ±0.1%.

If the linearity is ±0.5% FS, it means the maximum deviation of the output curve from the theoretical straight line is ±0.5%.

Conclusion: Linearity and accuracy are independent performance indicators. Good linearity does not mean good accuracy; both must be evaluated separately.