Overview

- Unions, typically used for easy connection and disassembly of pipe components, utilize nuts for securing the union. They are widely used in small flow meter installations.

- Various tools are available for disassembling union nuts, including groove joint pliers, strap wrenches, pipe wrenches, and oil filter wrenches, each suitable for different situations and sizes.

Union and nut play crucial roles in many installation tasks, serving as reusable and easily detachable fittings. They are commonly seen in valves and flow meters. This article will introduce unions and provide a detailed explanation of how to operate the commonly used wrench tools for installing unions.

What is Union Fitting?

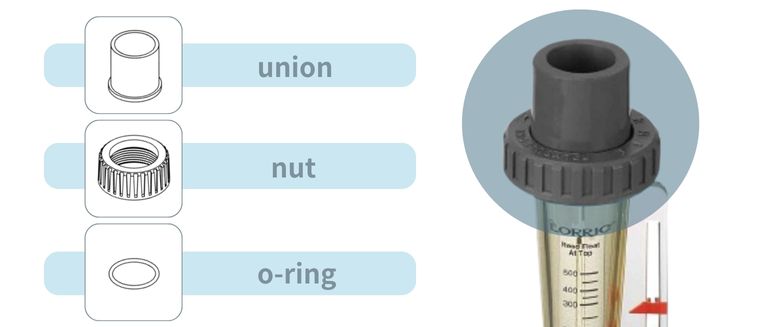

A union is a type of fitting used to connect components of a piping system. It allows for easy disassembly and reassembly, making maintenance convenient, and usually provides excellent sealing performance. The nut is used to secure the union components, while the o-ring prevents leaks.

Structure of a Union Fitting

Most commonly, union fittings are to be used on small size flowmeters for convenient installation. For larger size flow meters, the union fitting is relatively difficult to assemble or disassemble by hand. Therefore, wrenches or pliers are recommended to tighten and loosen large size unions.

A typical union fitting consists of three main parts:

•Nut: The core component of the union fitting, used to securely fasten two pipe sections together..

•O-ring: A sealing ring that prevents leaks.

•Union: The part that connects the flow meter to the pipeline.

Common Types of Union Fittings

- Socket Union: Both ends are socket-type, available in JIS (Japan), ANSI/ASTM (USA), DIN (Europe), and CNS (Taiwan) standards.

- Threaded Union: Available in female (internal) or male (external) threads, connecting to pipes via threading.

How to Loosen and Remove a Union Fitting?

To effectively loosen and remove a union fitting, follow these steps:

Turn Off Supply: Ensure the water or gas supply to the pipe system is turned off to prevent leaks or spills.

Secure Tools: Use two wrenches – one to hold one side of the union fitting firmly and the other to turn the opposite side counterclockwise.

Apply Penetrating Oil: If the fitting is stuck, apply penetrating oil to the threads and wait for about 15 minutes to allow the oil to penetrate and loosen any rust or corrosion.

Tap Lightly with a Hammer: Gently tap around the sides of the central nut using a hammer to help dislodge any rust .

Use Heat if Necessary: In some cases, applying heat with a heat gun or propane torch can expand the metal, making it easier to loosen. Use caution to avoid damaging the fitting.

Use a Larger Wrench for Better Leverage: If the fitting remains tight, using a larger pipe wrench can provide better leverage.

[1][2][3][4]

Union Wrench

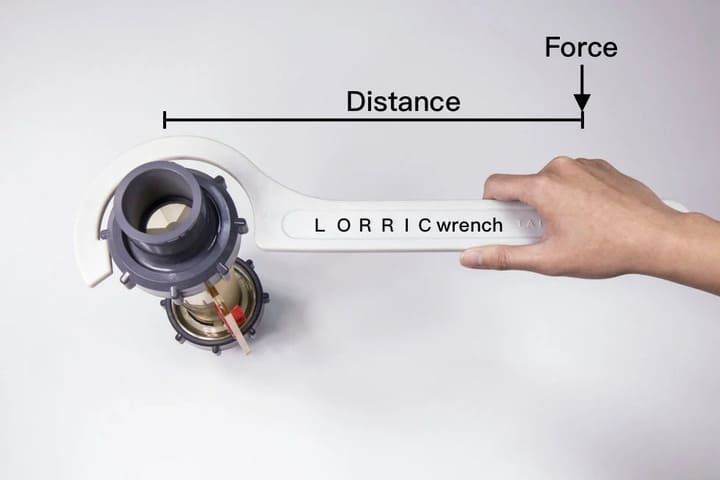

In response to user needs for better on-site user experience. LORRIC designed and produced a special union wrench fitted to 2’ large size flow meters based on the leverage theory (L= DxF). The cap wrench increases the contact area and can get the maximum torque with a small amount of force. This allows the user to easily install and remove large-size joints.

Common Union Wrenches

Channel Lock Pliers

Channel lock pliers have serrated jaws generally set 45 to 60 degrees from the handles. The lower jaw can be moved to a number of positions by sliding along a tracking section under the upper jaw. An advantage of this design is that the pliers can adjust to a number of sizes without the distance in the handle growing wider. These pliers often have long handles—commonly 9.5 to 12 inches long—for increased leverage.

[5]

Strap Wrench

A strap wrench grips an object via a strap or chain being pulled in tension around it until it firmly grips. High static friction keeps it from slipping.The strap or chain can have various forms. Some straps are made of polymers, and are smooth, highly flexible, non-marring, high-friction straps. Other straps are bands of spring steel, moderately flexible, slightly firmer and more likely to mar than the polymer variants. The chains tend to be of the roller chain type (like a bicycle chain).

[6]

Pipe Wrench

A pipe wrench is usually made of cast steel. Today, aluminium might be used to construct the body of the wrench, although the teeth and jaw remain steel. A pipe wrench is designed to turn threaded pipe and pipe fittings for assembly or disassembly.

[7]

Oil Filter Wrench

Chain-type oil-filter wrench

An oil-filter wrench is a tool for removing spin-on type oil filters.There are three common types. One type of wrench is shown on the right. The loop of chain is placed around the filter, and the bar is turned anticlockwise by hand until the chain wraps itself tightly around the filter. A socket wrench or adjustable spanner is then used to turn the hexagonal bar further in the same direction.(Photo:wikimedia)

Metal Swivel Oil Filter Wrench

Another type uses a metal band that is attached at both ends to a handle. The looped band is placed around the filter and the handle is turned anticlockwise, which puts tension on the band, causing it to grip the filter.

Ratchet Oil Filter Wrench

The third common type of wrench utilizes a metal or plastic cup that is shaped much like a socket. The cup is placed on the end of the filter, which engages the knurling. A socket or wrench is then used to loosen the filter.

[8]