Published: 2025-09-01 Last Updated: 2025-09-01

Background

With climate change and global urbanization accelerating, pressure on water resources, demand for industrial water efficiency,

and environmental regulations are all driving rapid growth of the water treatment industry.

According to Grand View Research, the global water pump market was valued at USD 71.86 billion in 2024

and is projected to reach USD 92.22 billion by 2030, with a CAGR of 4.4%.

In addition, MarkNtel Advisors reports that the pumps used in the chemical industry segment

is expected to grow from USD 5.88 billion in 2024 to USD 6.88 billion by 2030, with a CAGR of 3.06%.

The Role and Applications of NaOH in Water Treatment

Sodium hydroxide (NaOH, also known as caustic soda) is one of the most widely used basic chemicals in water treatment.

It is mainly applied to neutralize acidic wastewater, adjust pH levels, prepare coagulants to promote sedimentation,

and stabilize chlorine disinfection in municipal water treatment.

Because NaOH is highly corrosive, the transfer process places strict demands on pump materials and long-term stability.

Choosing the right NaOH transfer pump solution is therefore a critical part of any water treatment system.

[1][2]

📌 NaOH Transfer in Water Treatment: How to Reduce Energy Use, Noise, and Enhance Automation?

Case Study Client – Hardman Chemicals / DGL Group, Australia’s Hazardous Chemical Logistics and Water Treatment Chemical Supplier

Current Situation

Hardman Chemicals / DGL Group is one of Australia’s leading hazardous chemical logistics and water treatment chemical suppliers.

At its facilities, sodium hydroxide (NaOH) solution transfer relies heavily on pumping equipment.

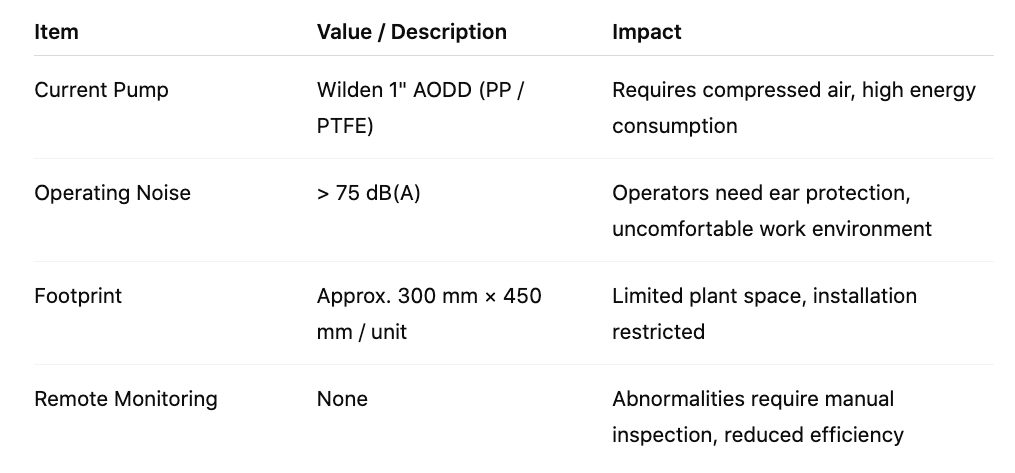

In the past, Hardman Chemicals used a Wilden 1" Air-Operated Double Diaphragm Pump (AODD) for NaOH transfer, but encountered issues such as high noise levels and limited installation space.

Improvement Goals

- 1. Reduce energy consumption

- 2. Lower noise and improve working environment

- 3. Decrease maintenance frequency and cost

- 4. Provide PLC connectivity for automated monitoring

- 5. Retain self-priming and dry-run capability of diaphragm pumps

💡QUANTM EODD Pump Eliminates AODD’s High Energy Use and Noise Issues

In the existing NaOH water treatment transfer system, Hardman Chemicals replaced its air-operated diaphragm pump directly with the QUANTM i30 electric diaphragm pump.

This upgrade improved energy efficiency, reduced noise and maintenance costs, and enabled smart monitoring via PLC integration.

- 5× Higher Energy Efficiency: No longer reliant on compressed air, significantly reducing energy consumption.

- Quieter Operation: Noise reduced from >75 dB to ~61 dB, improving the working environment.

- Lower Maintenance Costs: Eliminates compressed air piping and compressor maintenance.

- No Extra Footprint: Compact 250 × 310 mm pump size, fits directly into existing frames.

- Smart Monitoring: Built-in Modbus-RTU, connects directly to PLC for real-time reporting.

🔧 How Does the EODD Pump Meet Performance Needs for NaOH Transfer in Water Treatment?

By replacing air operation with a direct-drive brushless motor and integrating Modbus-RTU with PLC, QUANTM achieves five key performance targets: higher efficiency, lower noise, no compressed air, zero footprint increase, and remote monitoring.

| Goal |

QUANTM Solution |

| 🎯 Reduce Energy Consumption |

✔ Electric motor drive, no compressed air required, 5× more efficient than AODD pumps; significantly lowers energy costs. |

| 🎯 Lower Noise, Improve Work Environment |

✔ Brushless motor runs quietly and smoothly; noise reduced from >75 dB to ~61 dB, eliminating need for ear protection. |

| 🎯 Reduce Maintenance Frequency and Cost |

✔ Eliminates compressed air piping and compressor maintenance; longer pump life and reduced downtime. |

| 🎯 Enable PLC Integration for Automated Monitoring |

✔ Built-in I/O and Modbus-RTU connect directly to PLC; real-time data reporting to SCADA system. |

| 🎯 Retain Self-Priming and Dry-Run Capability |

✔ Supports 6 m suction lift and 30 min dry-run; restarts without priming, ensuring safe chemical transfer and CIP processes. |

FAQ

Q1: What type of pump is used for sodium hydroxide (NaOH) transfer?

A: Sodium hydroxide (NaOH) is a highly corrosive alkali. Long-term contact can damage pump bodies and piping. If materials are not corrosion-resistant, leaks and frequent maintenance occur. Therefore, electric diaphragm pumps with PP bodies and PTFE diaphragms are recommended for stable and durable NaOH transfer.

Q2: What common challenges arise when transferring NaOH in water treatment?

A: In water treatment systems, NaOH transfer faces several issues. Traditional AODD pumps rely on compressed air, resulting in low energy efficiency. Noise during operation affects worker comfort. Strong corrosion of NaOH on seals leads to frequent shutdowns and maintenance. Furthermore, the lack of digital monitoring means abnormalities must be checked manually, reducing overall system efficiency.

Q3: How can cavitation or dry-run risks be avoided when pumping NaOH?

A: To avoid cavitation or dry-run, ensure the pump has sufficient self-priming capacity and dry-run tolerance.

QUANTM maintains the self-priming and dry-run capabilities of diaphragm pumps, with a suction lift up to 6 m and 30 minutes dry-run tolerance, reducing cavitation and downtime risks in NaOH transfer.

Q4: What advantages does QUANTM offer in NaOH dosing for industrial wastewater treatment?

A: QUANTM not only ensures precise flow and pressure control but also connects via Modbus-RTU to PLCs, enabling real-time NaOH dosing data reporting. This ensures stable pH adjustment and compliance with discharge regulations.