Tổng Quan

- Giải pháp Tùy Chỉnh: Đặc tả vòi phun tùy chỉnh và báo cáo chi tiết về hiệu suất.

- Lựa Chọn Đa Dạng: Bộ sưu tập rộng lớn giúp nâng cao hiệu quả và tiết kiệm chi phí.

- Đảm Bảo Chất Lượng: Kiểm soát nghiêm ngặt để đảm bảo tuân thủ các yêu cầu kỹ thuật, đạt chứng nhận ISO.

- Vượt Trội Hơn Các Sản Phẩm Thương Mại: Các đặc tính, hiệu suất và chất lượng tốt hơn.

Tùy Chỉnh và Chất Lượng: LORRIC cung cấp giải pháp vòi phun tùy chỉnh với báo cáo hiệu suất chi tiết, đảm bảo đáp ứng nhu cầu chuyên biệt với độ chính xác và đảm bảo chất lượng, khác biệt so với các thương hiệu thông thường. Cam kết của LORRIC đối với nghề thủ công được thể hiện trong các dịch vụ hiệu suất và tùy chỉnh chi tiết của vòi phun, mang đến nhiều lựa chọn và đảm bảo chất lượng, chứng minh vị thế dẫn đầu của họ trong ngành. Chúng tôi sẽ khám phá cách LORRIC tích hợp nghệ thuật thủ công vào công nghệ vòi phun để đáp ứng nhu cầu công nghiệp hiện đại.

1. Từ Thủ Công đến Quản Lý ISO 9001, Vòi Phun LORRIC Đạt Tiêu Chuẩn Chất Lượng Cao

Được thành lập vào năm 1991, tay nghề thủ công kiên định của LORRIC luôn là yếu tố cốt lõi, lựa chọn vật liệu cao cấp và tận dụng kiến thức kỹ thuật sâu rộng được xây dựng từ những kinh nghiệm sâu sắc với người sử dụng và các nhà sản xuất thiết bị. Với kỹ thuật của các thợ thủ công có kinh nghiệm, LORRIC tạo ra các vòi phun chính xác khác biệt so với những sản phẩm kém chất lượng phổ biến. Kể từ năm 2018, LORRIC đã nâng cao hệ thống quản lý chất lượng của mình thông qua chứng nhận ISO 9001:2015, đảm bảo rằng mọi vòi phun rời khỏi nhà máy đều đáp ứng các yêu cầu thiết kế cho các ứng dụng công nghiệp hiệu quả cao.

2. Dịch Vụ Hiệu Suất Chi Tiết và Tùy Chỉnh Của Vòi Phun LORRIC

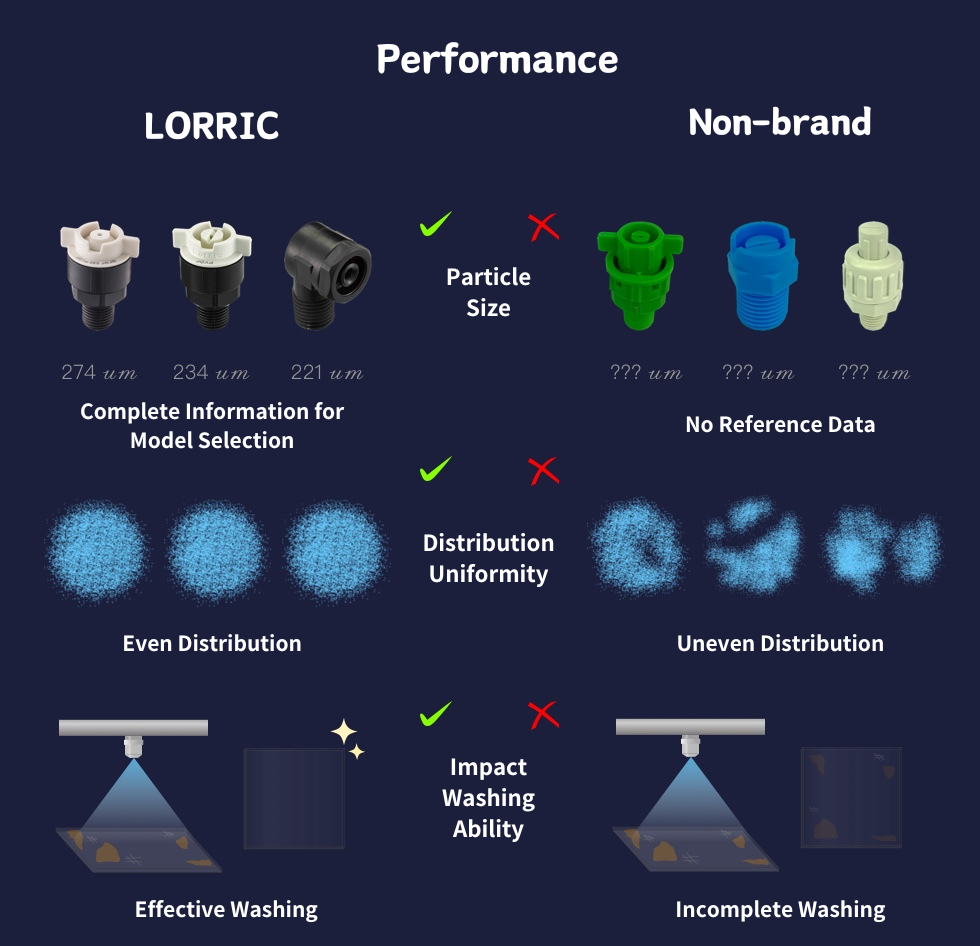

Tay nghề của LORRIC tập trung vào các khía cạnh hiệu suất chi tiết của vòi phun như kích thước hạt, sự đồng đều của phân bố, và khả năng làm sạch. Họ cung cấp các dịch vụ "Kiểm Tra Vòi Phun" và "Phát Triển Vòi Phun Tùy Chỉnh" dựa trên nhu cầu của khách hàng về lưu lượng, góc phun, và phân bố, cùng với các báo cáo hiệu suất toàn diện. Điều này cho phép khách hàng với các yêu cầu vòi phun và hiệu suất đặc biệt có được các giải pháp phun hoàn hảo.

- Kích thước hạt: Mỗi vòi phun đi kèm với báo cáo chi tiết về kích thước hạt phun trung bình, giúp lựa chọn dựa trên các ứng dụng công nghiệp khác nhau.

- Phân bố (Đồng đều): Cho phép tùy chỉnh tỷ lệ phân bố phun ở các vị trí khác nhau theo yêu cầu thiết kế hệ thống, đảm bảo hiệu suất ổn định cho mọi vòi phun.

- Ảnh hưởng (Lực làm sạch): Đảm bảo lực phun đồng đều, làm sạch hiệu quả trong một khu vực xác định.

3. Tìm Hiểu Sâu Về Các Nền Tảng Công Nghiệp, Xây Dựng Các Đặc Tính Vòi Phun Toàn Diện Để Đáp Ứng Nhu Cầu Nhiều Mặt

Vòi phun là các thành phần thụ động trong hệ thống phun kiểm soát phương pháp phun chất lỏng. Việc thiết kế vòi phun theo thông số kỹ thuật hệ thống tạo ra một hệ thống phun hiệu quả và tiết kiệm chi phí. LORRIC hợp tác chặt chẽ với các nhà sản xuất thiết bị hệ thống phun, không ngừng tìm hiểu các nền tảng để hiểu rõ nhu cầu của người sử dụng. Dòng sản phẩm vòi phun của LORRIC cung cấp các "lưu lượng" và "góc phun" khác nhau, cho phép khách hàng tự tin lựa chọn vòi phun phù hợp nhất với thiết kế hệ thống của họ, đảm bảo rằng việc thiếu lựa chọn thông số không làm cản trở thiết kế hệ thống tổng thể.

( 1 ) Các mẫu phun, lưu lượng, góc và vật liệu đa dạng giúp giảm chi phí và nâng cao hiệu quả hệ thống:

- Đa dạng các mẫu phun: Bao gồm phun dạng quạt, phun hình nón, phun hình nón rỗng, phun cột, và phun xoắn, LORRIC cung cấp nhiều lựa chọn để đáp ứng yêu cầu thiết kế hệ thống.

- Lưu lượng đa dạng: Phù hợp cho các hệ thống phức tạp với các dòng ống và áp suất khác nhau, LORRIC có vòi phun cho mọi ứng dụng.

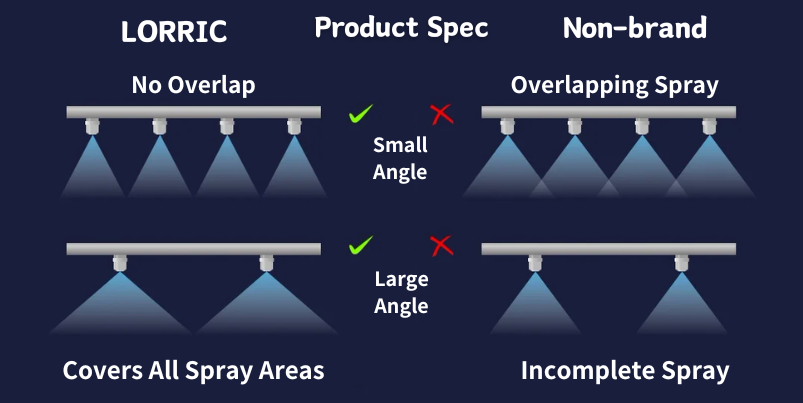

- Góc phun đa dạng: Vòi phun có thể được chọn dựa trên chiều cao hệ thống và khu vực, đảm bảo bao phủ đầy đủ mà không lãng phí, kiểm soát chi phí.

- Vật liệu khác nhau: Đáp ứng các yêu cầu ngành công nghiệp về khả năng chống ăn mòn và chịu đựng môi trường hóa chất, LORRIC cung cấp nhiều vật liệu, đảm bảo độ bền, bảo trì thấp và hiệu quả chi phí. Thêm vào đó, LORRIC đảm bảo sử dụng vật liệu chính hãng, không tái chế, mang lại sự tin cậy cho khách hàng đối với vòi phun của họ.

( 2 ) Vòi Phun LORRIC Chất Lượng Cao Đảm Bảo Hiệu Suất Đồng Đều

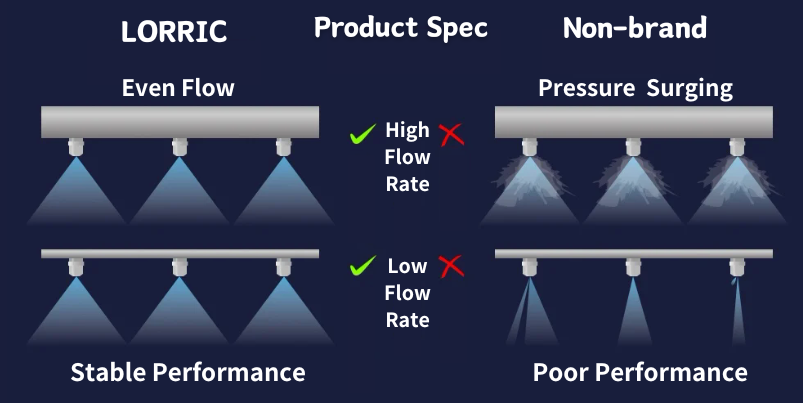

a) Dòng Chảy Ổn Định Cho Tất Cả Các Kích Cỡ:

Dù là lưu lượng lớn hay nhỏ, vòi phun LORRIC đảm bảo phun ổn định mà không có các cơn vỡ hoặc mẫu phun không đồng đều, trái ngược với các thương hiệu thông thường, nơi lưu lượng lớn có thể bị vỡ và lưu lượng nhỏ phân tán, dẫn đến hiệu suất không đồng nhất.

b) Góc Phun Đồng Đều Cho Mọi Kích Cỡ:

Vòi phun LORRIC duy trì phân bố phun ổn định ở mọi góc độ, đảm bảo bao phủ không chồng lấn và ứng dụng chính xác, nâng cao hiệu quả dây chuyền sản xuất mà không lãng phí.

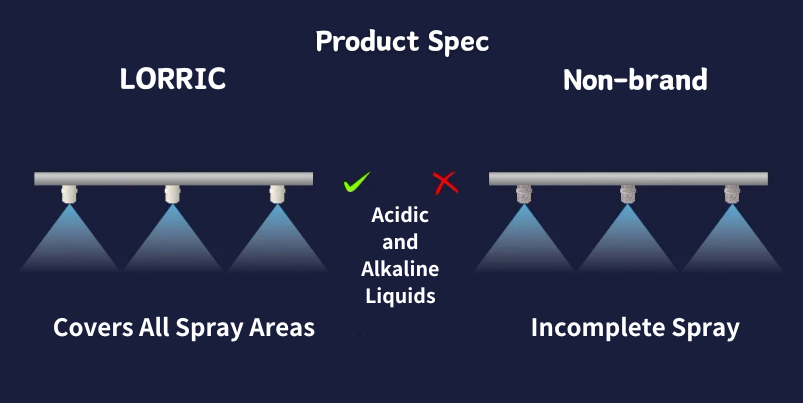

c) Vật Liệu Đa Dạng Cho Độ Bền:

Cung cấp các vật liệu như AISI303, AISI316, BRASS, HSS, PP, LORRIC đảm bảo vòi phun phù hợp với nhiều môi trường và hóa chất (chống ăn mòn), kéo dài tuổi thọ và giảm chi phí bảo trì.

4. Vòi Phun LORRIC Đảm Bảo Tolerances Để Đảm Bảo Hiệu Suất Đồng Đều

Độ chính xác và thực tiễn trong các môi trường công nghiệp là những lợi thế cạnh tranh quan trọng, nhấn mạnh tầm quan trọng của việc duy trì các phạm vi tolerance. Từ thiết kế ban đầu của hệ thống và thiết bị, bao gồm các thông số kỹ thuật của các thành phần, các phạm vi tolerance hiệu suất được xem xét để đảm bảo thiết kế hoạt động như mong đợi. Vòi phun LORRIC cung cấp độ tolerance dòng chảy ± 5% và độ tolerance góc ± 5°, đảm bảo hiệu suất hệ thống phun đồng đều, dẫn đến sản xuất công nghiệp hiệu quả và chất lượng cao. Cam kết về sự đồng đều và chất lượng này là lời hứa lâu dài của LORRIC đối với khách hàng, được thể hiện qua sự hợp tác tại chỗ.

5. Nghiên Cứu và Phát Triển, Sản Xuất và Kiểm Soát Chất Lượng Tất Cả Được Thực Hiện Tại LORRIC Đài Loan, Áp Dụng ISO 9001:2015

Tất cả các quy trình, từ nghiên cứu và phát triển đến sản xuất và kiểm soát chất lượng, đều được thực hiện trực tiếp tại Đài Loan, tuân thủ hệ thống quản lý ISO 9001:2015. Quản lý nghiêm ngặt và kiểm toán trong tất cả các giai đoạn đảm bảo việc cung cấp sản phẩm chất lượng cao liên tục. Cam kết của LORRIC đối với tay nghề, vốn là cốt lõi của DNA thương hiệu từ khi thành lập, thể hiện qua các yêu cầu chất lượng nghiêm ngặt, kiến thức rộng rãi thu được từ việc giải quyết các vấn đề của khách hàng tại chỗ, và tiêu chuẩn tolerance sản phẩm nghiêm ngặt. Để đưa DNA này vào mọi khía cạnh hoạt động của thương hiệu, LORRIC đã áp dụng tiêu chuẩn quản lý chất lượng quốc tế ISO 9001:2015 vào năm 2018, tập trung vào sự định hướng khách hàng, lãnh đạo, sự tham gia của con người, phương pháp quy trình, phương pháp quản lý hệ thống, cải tiến liên tục, và quyết định dựa trên dữ liệu. Quy trình lập kế hoạch và vận hành có cấu trúc này nâng cao quản lý chất lượng, đảm bảo hoạt động của LORRIC liên tục đáp ứng nhu cầu của khách hàng. [1]