Convenience and Maintenance

- The automation module adopts a clamping connection, making it easy to assemble and disassemble.

- Features a fully plastic exterior structure, which is aesthetically pleasing and corrosion-resistant.

- Precise screw fit with clearance for smooth, maintenance-free operation.

- Does not rely on the presence of a compressed air system.

- Integrated LED interface for easy setting and monitoring.

- Allows manual upgrades without interrupting the production line.

High Safety Performance

- Stronger casing, suitable for more corrosive environments.

- Suspended diaphragm coupling mechanism provides full protection to the diaphragm.

- All products' torque is independently verified to ensure product longevity.

High Flexibility

- Connection types include socket fusion and butt welding.

- Interface standards include metric, JIS (Japanese Industrial Standards), and ANSI (American National Standards Institute).

- Diaphragm materials: EPDM, FPM, EPDM-PTFE.

- Valve body materials: PVC-U, PVC-C, PP-H, PP-N, PVDF. * Some products offer oil-free options.

Optimal Flow Performance

- Rated voltage: AC/DC24V, AC95-265V.

- Control methods: 4-20mA, 0-20mA, 0-5V, 1-5V, 2-10V.

- Feedback method: 4-20mA.

- Alarm output signal: Relay contact, optional.

- Position accuracy: ±1%. * Equipped with a high-performance brushless motor with built-in overcurrent and overload protection.

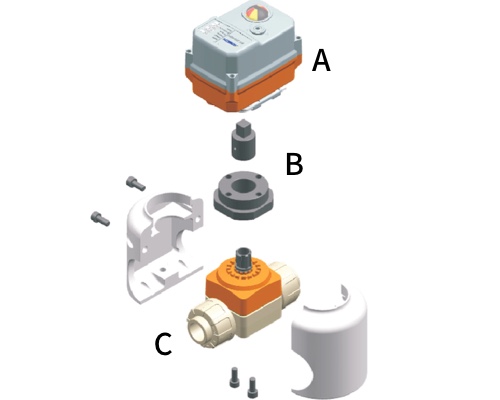

Disassembled Components and Material Structure Selection

| NO |

Part Names |

Materials |

| A |

Electric Actuator |

- Upgrades and expands on existing manual diaphragm valves in pipeline systems.

- Enables online installation without the need for shutdown.

- Features IP67 protection rating.

- Offers online closed position calibration settings.

- Beyond on/off functionality, it is suitable for proportional control adjustments.

- Offers a variety of input and output options to meet different system requirements.

- Has an all-plastic housing for chemical resistance.

- Includes an intuitive valve position indicator window.

|

| B |

Mounting Bracket |

- Chemical-resistant PP wrapped bracket.

- Equipped with mounting nuts at the base for easy installation.

- Simplifies installation when expanding manual diaphragm valves online.

- Features a rotation mechanism with superior wear resistance compared to manual diaphragm valves.

- Standard in white, with custom colors available upon request. |

| C |

Diaphragm Valve Body |

- Exhibits excellent linear fluid dynamics for control functions.

- Smooth transitional flow paths provide double the flow capacity of traditional diaphragm valves.

- Suitable for media containing small particles and solids.

- Seamless integration of diaphragm and valve body eliminates dead zones.

- Enhanced diaphragm structure for improved fatigue life.

- Applicable for both on/off and control adjustments in vacuum systems. |

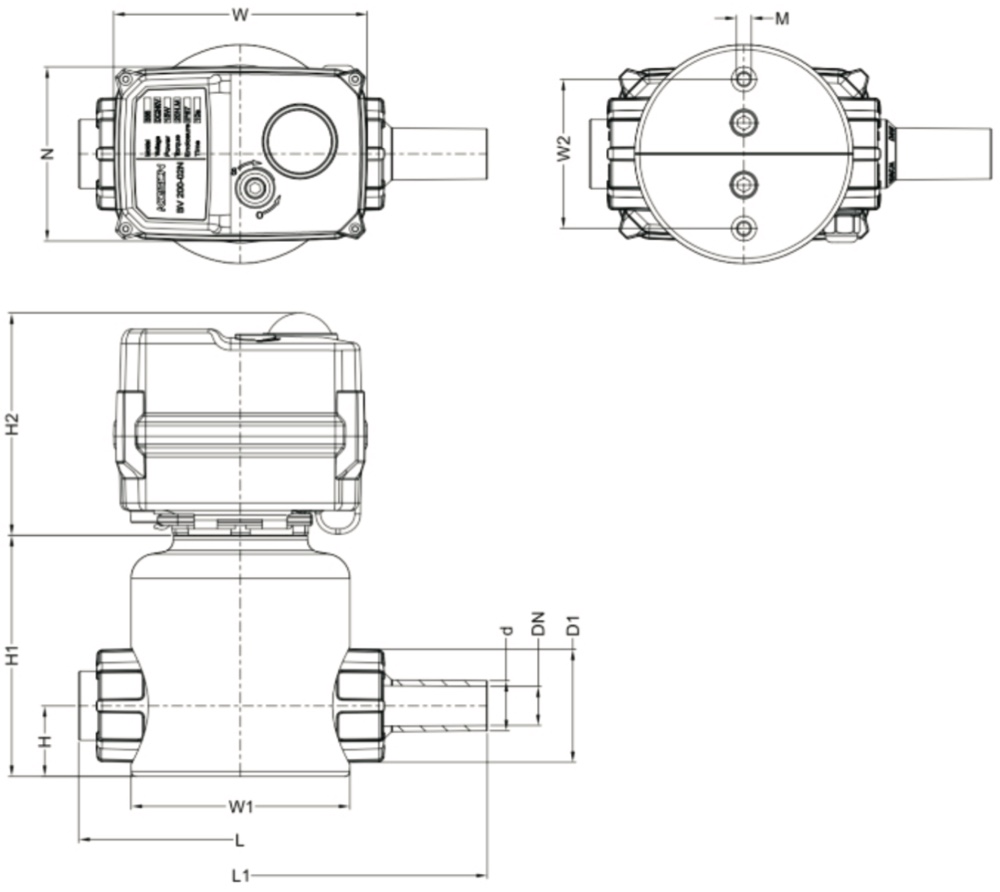

Size

| d |

DN |

GD |

D1 |

H |

H1 |

H2 |

L |

L1 |

N |

W |

W1 |

W2 |

M |

| 20 |

15 |

1 |

46 |

29 |

97 |

90 |

128 |

196 |

70 |

102 |

89 |

60 |

M6 |

| 25 |

20 |

1-1/4 |

56 |

35 |

109 |

90 |

152 |

221 |

70

|

102 |

112 |

60 |

M6 |

| 32 |

25 |

1-1/2 |

66 |

39 |

143 |

90 |

166 |

234 |

70

|

102 |

139 |

80 |

M8 |

| 40 |

32 |

2 |

79 |

44 |

148 |

90 |

192 |

260 |

70

|

102 |

139 |

80 |

M8 |

| 50 |

40 |

2-1/4 |

86 |

53 |

196 |

120 |

222 |

284 |

111 |

132 |

164 |

80 |

M8 |

| 63 |

50 |

2-3/4 |

108 |

63 |

206 |

120 |

266 |

321 |

111 |

132 |

184 |

80 |

M8 |

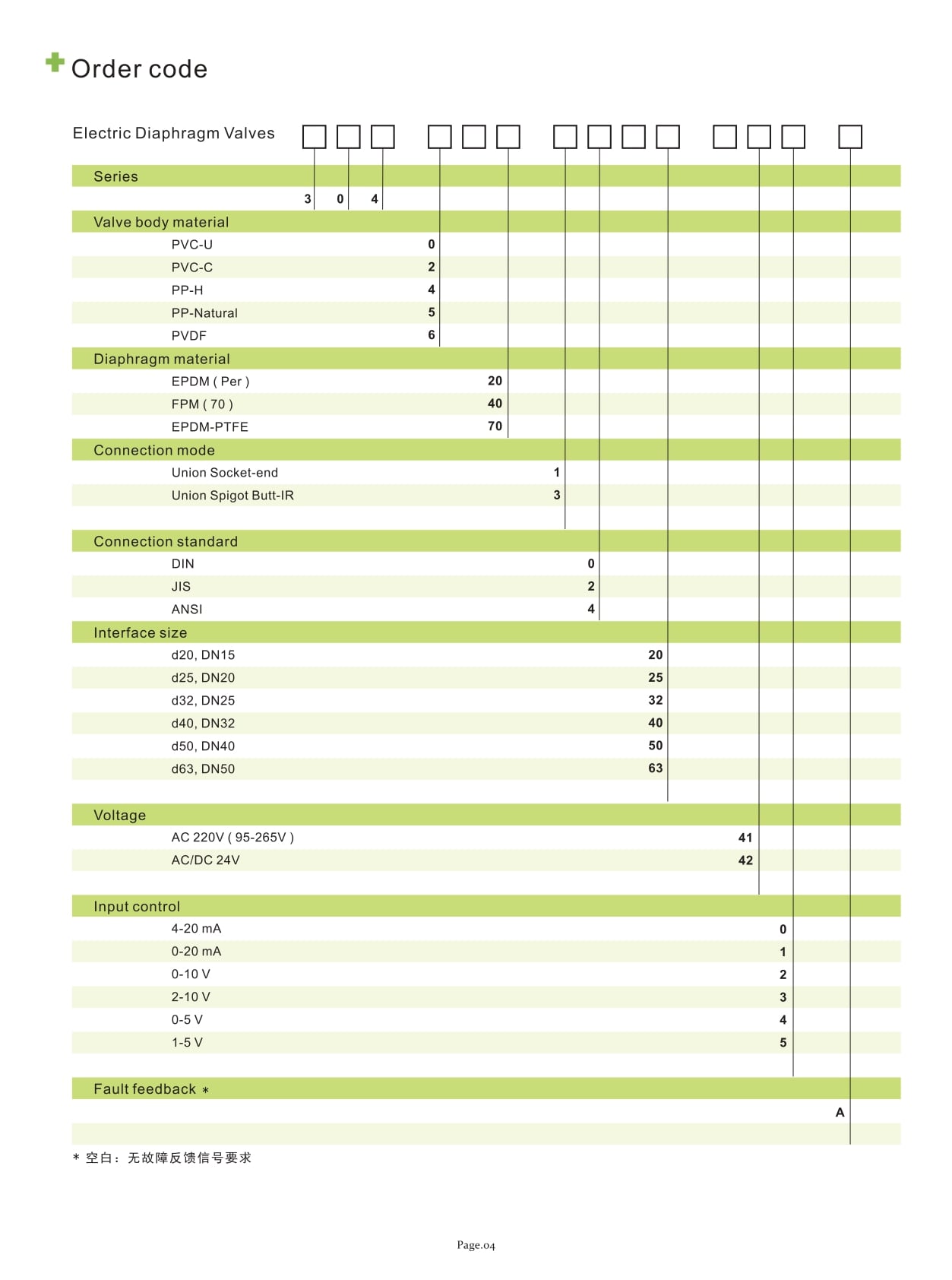

Select Code Based on Requirements

Pressure-Temperature Curves

Data based on clean water media and a 25-year safety life; applications with other media must reduce temperature and pressure.

Flow Capacity

Data based on 20°C clean water media and a 1 bar pressure difference;

Cv = Kv X 0.07

Fv = Kv X 0.0585

Kv (l/min)

Cv (gal/min) US

Fv (gal/min) GB

Relative Flow Linearity Graph

The relative flow linearity coefficient refers to flow variation as a function of valve opening travel.

KOSCN

KOSCN Industrial Manufacturing (Shenzhen) Co., Ltd., founded in 2005 and headquartered in Shenzhen, China, operates globally with subsidiaries and agent teams. It offers comprehensive pre-sales and after-sales services worldwide. KOSCN has a professional R&D, design, and production team, adhering strictly to ISO9001, ISO14001, and ISO45001 standards to ensure the highest product quality.

KOSCN's products, mainly automated valves for ultra-pure and corrosive systems, are widely used in semiconductor, glass panel, electroplating, wastewater treatment, waste liquid solidification, solar energy, landfill leachate, PCB, metallurgy, steel, ultra-pure water, recycling, chemical, food and beverage, power, paper, biopharmaceutical, and biofermentation industries.

Download: KOSCN Product Brochure