A union fitting is a connection used for convenient assembly and disassembly of a device and/or pipe. The union nut is essential in the process of joining a union fitting on a pipe or other device.

Most commonly, union fittings are to be used on small size flowmeters for convenient installation. For larger size flow meters, the union fitting is relatively difficult to assemble or disassemble by hand. Therefore, wrenches or pliers are recommended to tighten and loosen large size unions.

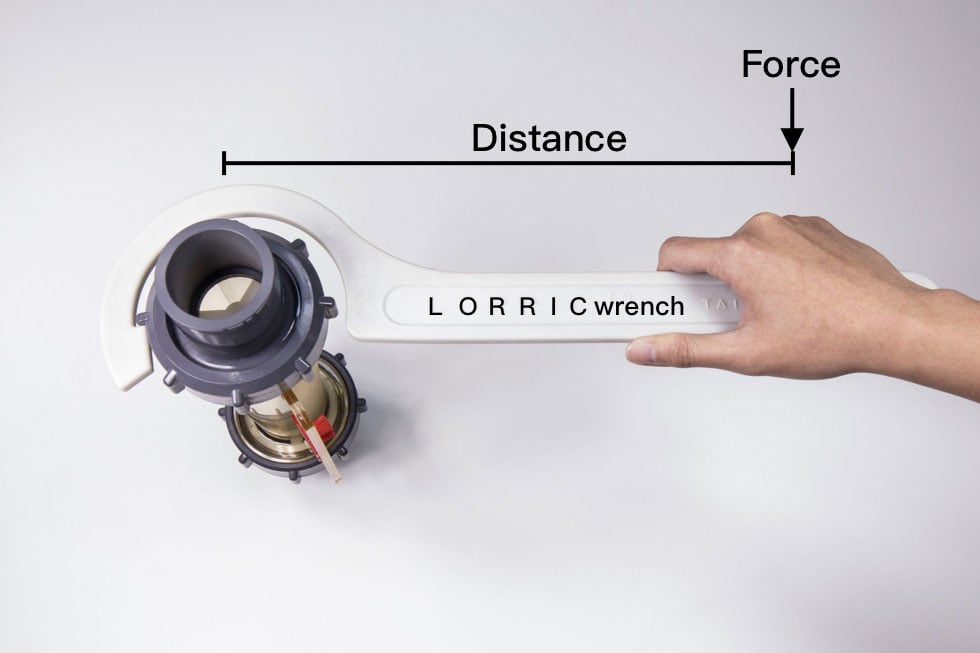

In response to user needs for better on-site user experience. LORRIC designed and produced a special union wrench fitted to 2’ large size flow meters based on the leverage theory (L= DxF). The cap wrench increases the contact area and can get the maximum torque with a small amount of force. This allows the user to easily install and remove large-size joints.

Following, we will introduce some common union wrenches for your reference.

1. Channel Lock Pliers

Channel lock pliers have serrated jaws generally set 45 to 60 degrees from the handles. The lower jaw can be moved to a number of positions by sliding along a tracking section under the upper jaw. An advantage of this design is that the pliers can adjust to a number of sizes without the distance in the handle growing wider. These pliers often have long handles—commonly 9.5 to 12 inches long—for increased leverage.

(Citing source: Tongue-and-groove pliers, https://en.wikipedia.org/wiki/Tongue-and-groove_pliers)

2. Strap Wrench

A strap wrench grips an object via a strap or chain being pulled in tension around it until it firmly grips. High static friction keeps it from slipping.The strap or chain can have various forms. Some straps are made of polymers, and are smooth, highly flexible, non-marring, high-friction straps. Other straps are bands of spring steel, moderately flexible, slightly firmer and more likely to mar than the polymer variants. The chains tend to be of the roller chain type (like a bicycle chain).

(Citing source: Strap wrenc, https://en.wikipedia.org/wiki/Strap_wrench)

3. Pipe Wrench

A pipe wrench is usually made of cast steel. Today, aluminium might be used to construct the body of the wrench, although the teeth and jaw remain steel. A pipe wrench is designed to turn threaded pipe and pipe fittings for assembly or disassembly.

(Citing source: Pipe wrench, https://en.wikipedia.org/wiki/Pipe_wrench)

4. Oil Filter Wrench

An oil-filter wrench is a tool for removing spin-on type oil filters.There are three common types. One type of wrench is shown on the right. The loop of chain is placed around the filter, and the bar is turned anticlockwise by hand until the chain wraps itself tightly around the filter. A socket wrench or adjustable spanner is then used to turn the hexagonal bar further in the same direction.

(Citing source: Oil-filter wrench, https://en.wikipedia.org/wiki/Oil-filter_wrench)

(Citing source: Heron2 - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=1979019)

Another type uses a metal band that is attached at both ends to a handle. The looped band is placed around the filter and the handle is turned anticlockwise, which puts tension on the band, causing it to grip the filter.

(Citing source: Oil-filter wrench, https://en.wikipedia.org/wiki/Oil-filter_wrench)

The third common type of wrench utilizes a metal or plastic cup that is shaped much like a socket. The cup is placed on the end of the filter, which engages the knurling. A socket or wrench is then used to loosen the filter.

(Citing source: Oil-filter wrench, https://en.wikipedia.org/wiki/Oil-filter_wrench)

Liên hệ chúng tôi