1. What is spray?

The Interaction of Pressure + Nozzle Structure + Fluid Properties (incl. Viscosity and Surface Tension)

2. Fan Spray

When the liquid passes the orifice through the pressure special for the fan spray nozzle, the disturbance is generated through the process. Under the effects of disturbance, surface tension, and viscosity, the spray-out liquid becomes a fan shaped continuous surface with a certain angle. With continuous disturbance, the liquid gradually becomes atomized and crushed.

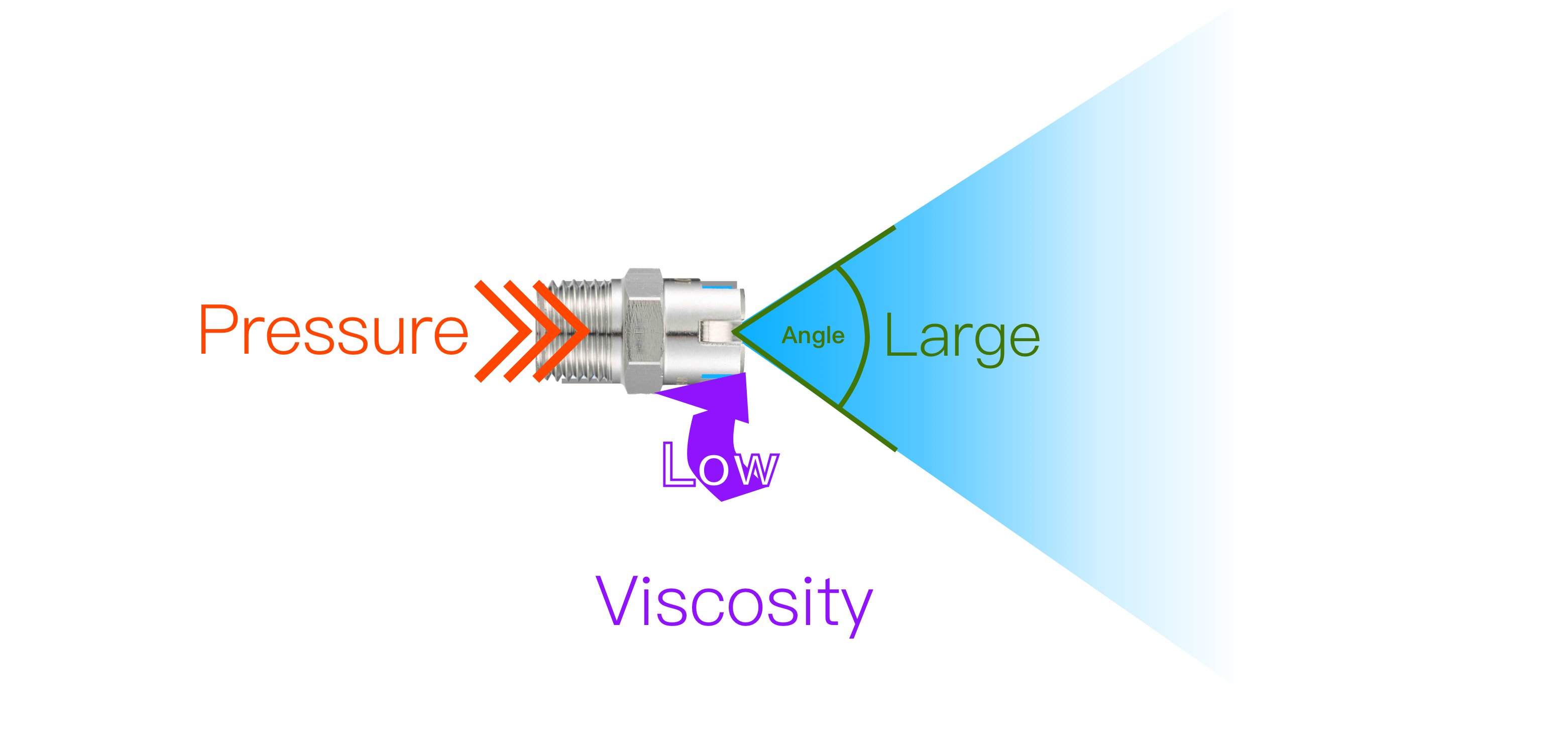

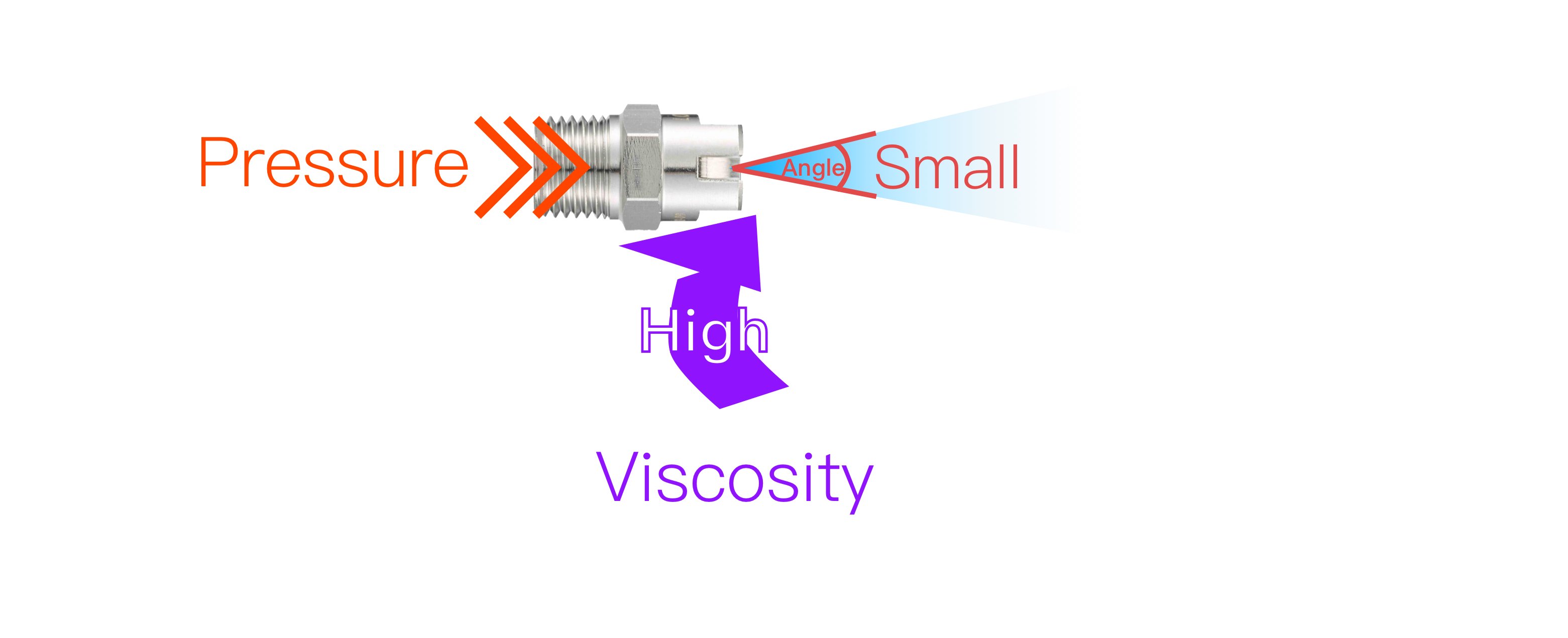

Generally speaking, the larger the orifice the greater the flow. Shape and diameter of the orifice affect the spray result and distribution. When the liquid passes by the nozzle orifice with the pressure, through the surface tension and viscosity, it will become a continuous surface to both sides at a certain angle of distribution. The liquid’s properties and the strength of pressure will directly affect the angle size of the spray.

Low liquid viscosity makes a larger spray angle.

High liquid viscosity makes a smaller spray angle and no atomization.

In terms of pressure, the less pressure the smaller the disturbance, and the continuous surface generated by spraying liquid will be larger. Otherwise, the larger the pressure, the larger the disturbance, and the continuous surface generated by spraying liquid will be smaller.

Pressure + Nozzle’s Structure + fluid properties (incl. viscosity and surface tension) = The shape of fan spray (size of the angle and the continuous surface)