Abstract

- Before installing a flow meter, ensure the pipe is free of air bubbles and solid particles to maintain measurement accuracy.

- Install the flow meter on a vertical straight pipe, away from elbows and valves, to ensure stable fluid flow.

- Align the flow meter's direction with the actual flow direction indicated on the device. Regularly inspect and clean the flow meter to maintain accuracy.

1. Installation Steps

Area flowmeters are widely used in industrial production due to their simple structure and convenient installation. This article will introduce the installation methods of area flowmeters and the precautions during installation.

Step 1

Before installation: Ensure the rotameter is installed on a vertical pipe with sufficient straight pipe length. The fluid should flow from bottom to top, matching the meter's direction.

%20(1).png)

Step 2

Disassemble the connections and inspect the rotameter for any damage.

%20(1).png)

Step 3

Install the fittings and O-rings, ensuring both ends have O-rings to prevent leaks.

Threaded fittings

Use Teflon tape on threaded connections for a better seal.

Insertion fittings

For insertion fittings, apply glue to both the inside of the fitting and the outside of the pipe.

Step 4

Allow the PVC glue to fully dry and the fumes to dissipate before tightening. Once ready, hand-tighten the nuts to secure the flow meter to the fittings.

2. Special Notices

1. Certain flowmeters contain magnetic materials – ensure that these fit your needs.

2. The following tips are advised in order to prevent damaging the flowmeter and void its warranty:

● The PC body can only tolerate clean tap water without any chemicals, cleaning detergents or other solvents.

● Both PC and PSU materials cannot tolerate organic compounds which might damage the flowmeter.

● Before making a purchase, validate that the flowmeter’s various parts are suitable for your purposes regarding factors such as operating temperatures, as every industry has different requirements

● The flowmeter’s body materials, PC and PSU, both cannot tolerate the following substances:

- PVC glue and the fumes it emits, and PVC lubricants (oils or ointments).

- Therefore, since the adaptor was glued to the main pipe using a PVC lubricant, the flowmeter body can only be installed after the PVC lubricant is completely dry.

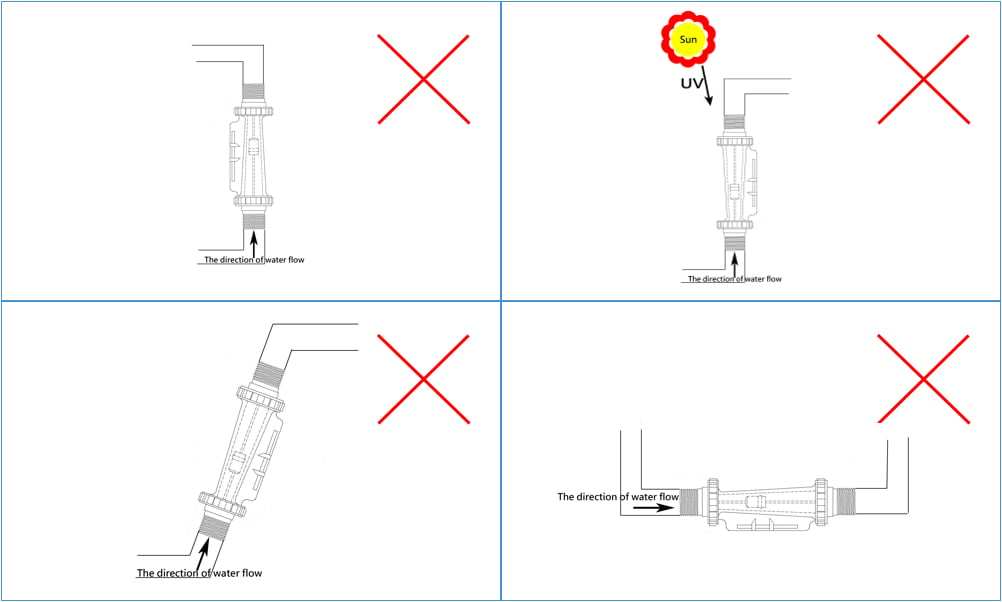

● Flowmeters must be installed perpendicularly to the ground to ensure proper accuracy. Misalignment may cause the O-ring seals to leak and thus reduce the flowmeter’s lifetime.

● Tighten the union nuts only using your bare hands, and refrain from using tools. Installation using inappropriate tools may cause the union nuts, adaptors, thread or seal to break.

● Flowmeters cannot be used to support pipeline, so please make sure the main pipe is installed firmly.

● Incorrect pipe installation may cause leakage and damage to the flowmeter.

● Water hammers might also damage flowmeters.

● UV radiation might damage the meter body, so please use a UV-resistant cover for the flowmeter when flowmeters are installed outdoors.

● Voluntarily dismantling or modifying the unit might cause damage.

● The maximum recommended working pressure to avoid damage is 6kg/cm2.

3. Mismeasurement might arise from the following reasons:

● The liquid’s specific gravity differs from the flowmeter’s specific gravity.

● The liquid contains particles of suspended matter.

3. Incorrect Installations