Accumulation of swarf on machine centers often causes one a headache.

Machines and tools during various machining processes tend to create a large amount of swarf that accumulates and often causes the user headaches and frustration. Therefore, how to effectively and inexpensively clear swarf is an important lesson for machine operators.

▲Go back to the Outline of this Article

Installation of a coolant hose is not an optimal solution.

Traditionally, users had a tendency to install adjustable coolant hoses to clear away swarf. These coolant hoses’ area of coverage however is insufficient, what causes the user to be forced to employ relatively large, power consuming pumps, thus wasting resources, water, and even cause water sinks to overflow. Despite these problems, these water coolants seemed to be the only solution, however expensive and inefficient of a solution it was.

▲Go back to the Outline of this Article

LORRIC nozzles – The optimal way to clear swarf!

F series, low pressure wide angle fan nozzle:Operating pressure: 0.7~3.0kg/cm² | Super wide angle: 145° | Flow rate: 0.28~16.7 l/min

H series, high pressure fan nozzle:High operating pressure: 1~10kg/cm² | multiple angles: 0~110° | Flow rate: 0.39~39.1 l/min

| F Series |

H Series |

| Low pressure |

High pressure |

| Low flow rate |

High flow rate |

| Spray angle: 145° |

Spray angle: 0°-100° |

| Suitable for cutting machines that create overflowable, but not easily adherable swarf. |

Suitable for cutting machines that create overflowable, but not easily adherable swarf. |

▲Go back to the Outline of this Article

Low water consumption ‧ Low power consumption pumps ‧ Fewer nozzles needed to be installed ▶ Low costs ‧ High efficiency

The fan spray composition and the wide angle design, combined with refined product machining guarantees that LORRIC nozzles create a consistent, identical and beautiful wide angle spray shape, that covers a wider area while using the same amount of water. Thus, in the same spraying range, fewer nozzles are needed to be installed, and thus fewer power consuming pumps are needed to be employed for the purpose of clearing swarf.

LORRIC nozzles VS. Adjustable coolant hoses

| |

LORRIC nozzles |

Adjustable coolant hoses |

| Cleaning capacity |

Good |

Bad |

| Water consumption |

0.28~40 l/min (Saving water) |

Above 15 l/min (Wasting water) |

| Spray width |

Spray angle: 0 to 145° |

Spray angle: Less than 60° |

| Pressure resistant |

under 10kg/cm² |

Within 2kg/cm² |

| Material |

Stainless steel, brass, plastic |

Only plastic |

|

Number of installations

needed for the same

machine center (one side)*

|

2、4、6 |

4、8、12 |

| Spec of pump |

1 HP |

1-1/2 ~ 2 HP |

| Cost of pump |

$4,000~5,000 |

$5,000~7,000 |

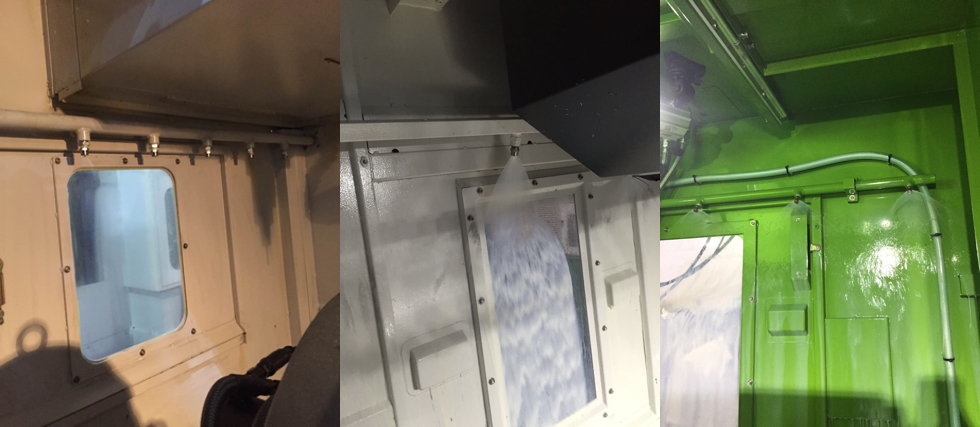

LORRIC nozzles installed in a machine center

▲Go back to the Outline of this Article

Machine center models with built-in LORRIC nozzles

Vertical machining center|CNC drilling & tapping center|CNC lathes

▲Go back to the Outline of this Article

Contact Us