Features

- The spraying type is fan type, and the spray shape is single

line and two sides are tapered (tapered edge), which presents

a bell curve shape flow field distribution with weaker ends

compared to the middle.

- Single-piece design, if there is frequent maintenance or

replacement requirements, it is recommended to use quick

install with multiple pieces nozzles.

- Recommended working pressure: 3.0 kgf/cm²

- Jet angle tolerance: 3°

- Flowrate tolerance:

● PP Material: ± 10% @ 3.0 ± 0.1 kgf/cm²

● Other Material: ± 5% @ 3.0 ± 0.1 kgf/cm²

- Angle tolerance:

● PP Material: ± 10° @ 3.0 ± 0.1 kgf/cm²

● Other Material: ± 5° @ 3.0 ± 0.1 kgf/cm²

- Applications:

● Cleaning: Vehicles, Containers, Filters, Dust, Gravel, Metals, Metal Parts, Machinery, Steel Plates, Various Containers, High Pressure Cleaning, Wet, Processing Display Pane, machine tool cleaning, etc.

● Cooling: gas, tank, machinery, metal, roof etc.;

● Dispersion: Humidifying, Chemicals (etching solution, lubricants, insect repellent, etc.), water

screens (fire, dust, deodorization etc.).

- Fan nozzle angle can be 0°~110°, 0° spray angle spray type

is straight column, spray Fog shape is a single point, providing

the best impact in all nozzle types.

- When the fan nozzle is used in high pressure environment,

choose HSS material (hardened stainless steel Steel), can

operate under 200Kg/cm² pressure.

Spray pattern & Flow distribution

Specs

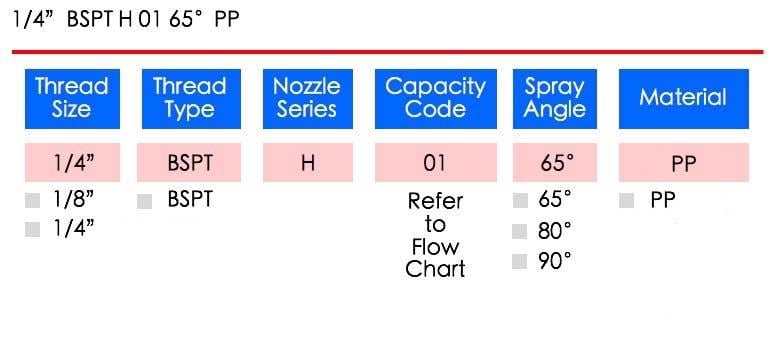

Please place your order according below information.

How to pleace an order for LORRIC nozzles?

- • You can find the exact Capacity Code according to your requirement of pressure, flow, and spray angle as the capacity & angle chart we provided above. Click to understand how to use the capacity & angle.

- • Please refer the to following order example for placing order to LORRIC.

- Example :

| Spray Angle |

Capacity Code |

Thread Size |

Capacity at Pressure |

Capacity at Pressure |

| 1/8" |

1/4" |

0.5

kgf/cm² |

1.0

kgf/cm² |

2.0

kgf/cm² |

3.0

kgf/cm² |

4.0

kgf/cm² |

6.0

kgf/cm² |

8.0

kgf/cm² |

10.0

kgf/cm² |

15.0

kgf/cm² |

| 65° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.45 |

0.55 |

0.64 |

0.71 |

0.87 |

| 65° |

02 |

V

|

V

|

0.32 |

0.45 |

0.64 |

0.78 |

0.90 |

1.11 |

1.28 |

1.43 |

1.75 |

| 65° |

2.5 |

V

|

V

|

0.40 |

0.56 |

0.80 |

0.98 |

1.13 |

1.38 |

1.60 |

1.78 |

2.19 |

| 65° |

03 |

V

|

V

|

0.48 |

0.68 |

0.96 |

1.17 |

1.35 |

1.66 |

1.92 |

2.14 |

2.62 |

| 65° |

04 |

V

|

V

|

0.64 |

0.90 |

1.28 |

1.56 |

1.81 |

2.21 |

2.55 |

2.86 |

3.50 |

| 65° |

05 |

V

|

V

|

0.80 |

1.13 |

1.60 |

1.96 |

2.26 |

2.76 |

3.19 |

3.57 |

4.37 |

| 65° |

06 |

V

|

V

|

0.96 |

1.35 |

1.92 |

2.35 |

2.71 |

3.32 |

3.83 |

4.28 |

5.25 |

| 65° |

07 |

V

|

V

|

1.12 |

1.58 |

2.23 |

2.74 |

3.16 |

3.87 |

4.47 |

5.00 |

6.12 |

| 65° |

7.5 |

V

|

V

|

1.20 |

1.69 |

2.39 |

2.93 |

3.39 |

4.15 |

4.79 |

5.35 |

6.56 |

| 65° |

08 |

V

|

V

|

1.28 |

1.81 |

2.55 |

3.13 |

3.61 |

4.42 |

5.11 |

5.71 |

6.99 |

| 65° |

09 |

V

|

V

|

1.44 |

2.03 |

2.87 |

3.52 |

4.06 |

4.98 |

5.75 |

6.42 |

7.87 |

| 65° |

10 |

V

|

V

|

1.60 |

2.26 |

3.19 |

3.91 |

4.51 |

5.53 |

6.39 |

7.14 |

8.74 |

| 65° |

12.5 |

V

|

V

|

2.00 |

2.82 |

3.99 |

4.89 |

5.64 |

6.91 |

7.98 |

8.92 |

10.93 |

| 65° |

15 |

V

|

V

|

2.39 |

3.39 |

4.79 |

5.87 |

6.77 |

8.29 |

9.58 |

10.71 |

13.11 |

| 65° |

20 |

V

|

V

|

3.19 |

4.51 |

6.39 |

7.82 |

9.03 |

11.06 |

12.77 |

14.28 |

17.49 |

| 65° |

25 |

|

V

|

3.99 |

5.64 |

7.98 |

9.78 |

11.29 |

13.82 |

15.96 |

17.85 |

21.86 |

| 65° |

30 |

|

V

|

4.79 |

6.77 |

9.58 |

11.73 |

13.54 |

16.59 |

19.16 |

21.42 |

26.23 |

| 65° |

35 |

|

V

|

5.59 |

7.90 |

11.17 |

13.69 |

15.80 |

19.35 |

22.35 |

24.99 |

30.60 |

| 65° |

40 |

|

V

|

6.39 |

9.03 |

12.77 |

15.64 |

18.06 |

22.12 |

25.54 |

28.55 |

34.97 |

| 65° |

50 |

|

V

|

7.98 |

11.29 |

15.96 |

19.55 |

22.57 |

27.65 |

31.93 |

35.69 |

43.72 |

| 65° |

60 |

|

|

9.58 |

13.54 |

19.16 |

23.46 |

27.09 |

33.18 |

38.31 |

42.83 |

52.46 |

| 65° |

80 |

|

|

12.77 |

18.06 |

25.54 |

31.38 |

36.12 |

44.24 |

51.08 |

57.11 |

69.94 |

| 65° |

100 |

|

|

15.96 |

22.57 |

31.93 |

39.10 |

45.15 |

55.30 |

63.85 |

71.39 |

87.43 |

| 80° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.45 |

0.55 |

0.64 |

0.71 |

0.87 |

| 80° |

02 |

V

|

V

|

0.32 |

0.45 |

0.64 |

0.78 |

0.90 |

1.11 |

1.28 |

1.43 |

1.75 |

| 80° |

2.5 |

V

|

V

|

0.40 |

0.56 |

0.80 |

0.98 |

1.13 |

1.38 |

1.60 |

1.78 |

2.19 |

| 80° |

03 |

V

|

V

|

0.48 |

0.68 |

0.96 |

1.17 |

1.35 |

1.66 |

1.92 |

2.14 |

2.62 |

| 80° |

04 |

V

|

V

|

0.64 |

0.90 |

1.28 |

1.56 |

1.81 |

2.21 |

2.55 |

2.86 |

3.50 |

| 80° |

05 |

V

|

V

|

0.80 |

1.13 |

1.60 |

1.96 |

2.26 |

2.76 |

3.19 |

3.57 |

4.37 |

| 80° |

06 |

V

|

V

|

0.96 |

1.35 |

1.92 |

2.35 |

2.71 |

3.32 |

3.83 |

4.28 |

5.25 |

| 80° |

07 |

V

|

V

|

1.12 |

1.58 |

2.23 |

2.74 |

3.16 |

3.87 |

4.47 |

5.00 |

6.12 |

| 80° |

7.5 |

V

|

V

|

1.20 |

1.69 |

2.39 |

2.93 |

3.39 |

4.15 |

4.79 |

5.35 |

6.56 |

| 80° |

08 |

V

|

V

|

1.28 |

1.81 |

2.55 |

3.13 |

3.61 |

4.42 |

5.11 |

5.71 |

6.99 |

| 80° |

09 |

V

|

V

|

1.44 |

2.03 |

2.87 |

3.52 |

4.06 |

4.98 |

5.75 |

6.42 |

7.87 |

| 80° |

10 |

V

|

V

|

1.60 |

2.26 |

3.19 |

3.91 |

4.51 |

5.53 |

6.39 |

7.14 |

8.74 |

| 80° |

12.5 |

V

|

V

|

2.00 |

2.82 |

3.99 |

4.89 |

5.64 |

6.91 |

7.98 |

8.92 |

10.93 |

| 80° |

15 |

V

|

V

|

2.39 |

3.39 |

4.79 |

5.87 |

6.77 |

8.29 |

9.58 |

10.71 |

13.11 |

| 80° |

20 |

V

|

V

|

3.19 |

4.51 |

6.39 |

7.82 |

9.03 |

11.06 |

12.77 |

14.28 |

17.49 |

| 80° |

25 |

|

V

|

3.99 |

5.64 |

7.98 |

9.78 |

11.29 |

13.82 |

15.96 |

17.85 |

21.86 |

| 80° |

30 |

|

V

|

4.79 |

6.77 |

9.58 |

11.73 |

13.54 |

16.59 |

19.16 |

21.42 |

26.23 |

| 80° |

35 |

|

V

|

5.59 |

7.90 |

11.17 |

13.69 |

15.80 |

19.35 |

22.35 |

24.99 |

30.60 |

| 80° |

40 |

|

V

|

6.39 |

9.03 |

12.77 |

15.64 |

18.06 |

22.12 |

25.54 |

28.55 |

34.97 |

| 80° |

50 |

|

V

|

7.98 |

11.29 |

15.96 |

19.55 |

22.57 |

27.65 |

31.93 |

35.69 |

43.72 |

| 80° |

60 |

|

|

9.58 |

13.54 |

19.16 |

23.46 |

27.09 |

33.18 |

38.31 |

42.83 |

52.46 |

| 80° |

80 |

|

|

12.77 |

18.06 |

25.54 |

31.38 |

36.12 |

44.24 |

51.08 |

57.11 |

69.94 |

| 80° |

100 |

|

|

15.96 |

22.57 |

31.93 |

39.10 |

45.15 |

55.30 |

63.85 |

71.39 |

87.43 |

| 90° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.45 |

0.55 |

0.64 |

0.71 |

0.87 |

| 90° |

02 |

V

|

V

|

0.32 |

0.45 |

0.64 |

0.78 |

0.90 |

1.11 |

1.28 |

1.43 |

1.75 |

| 90° |

2.5 |

V

|

V

|

0.40 |

0.56 |

0.80 |

0.98 |

1.13 |

1.38 |

1.60 |

1.78 |

2.19 |

| 90° |

03 |

V

|

V

|

0.48 |

0.68 |

0.96 |

1.17 |

1.35 |

1.66 |

1.92 |

2.14 |

2.62 |

| 90° |

04 |

V

|

V

|

0.64 |

0.90 |

1.28 |

1.56 |

1.81 |

2.21 |

2.55 |

2.86 |

3.50 |

| 90° |

05 |

V

|

V

|

0.80 |

1.13 |

1.60 |

1.96 |

2.26 |

2.76 |

3.19 |

3.57 |

4.37 |

| 90° |

06 |

V

|

V

|

0.96 |

1.35 |

1.92 |

2.35 |

2.71 |

3.32 |

3.83 |

4.28 |

5.25 |

| 90° |

07 |

V

|

V

|

1.12 |

1.58 |

2.23 |

2.74 |

3.16 |

3.87 |

4.47 |

5.00 |

6.12 |

| 90° |

7.5 |

V

|

V

|

1.20 |

1.69 |

2.39 |

2.93 |

3.39 |

4.15 |

4.79 |

5.35 |

6.56 |

| 90° |

08 |

V

|

V

|

1.28 |

1.81 |

2.55 |

3.13 |

3.61 |

4.42 |

5.11 |

5.71 |

6.99 |

| 90° |

09 |

V

|

V

|

1.44 |

2.03 |

2.87 |

3.52 |

4.06 |

4.98 |

5.75 |

6.42 |

7.87 |

| 90° |

10 |

V

|

V

|

1.60 |

2.26 |

3.19 |

3.91 |

4.51 |

5.53 |

6.39 |

7.14 |

8.74 |

| 90° |

12.5 |

V

|

V

|

2.00 |

2.82 |

3.99 |

4.89 |

5.64 |

6.91 |

7.98 |

8.92 |

10.93 |

| 90° |

15 |

V

|

V

|

2.39 |

3.39 |

4.79 |

5.87 |

6.77 |

8.29 |

9.58 |

10.71 |

13.11 |

| 90° |

20 |

V

|

V

|

3.19 |

4.51 |

6.39 |

7.82 |

9.03 |

11.06 |

12.77 |

14.28 |

17.49 |

| 90° |

25 |

|

V

|

3.99 |

5.64 |

7.98 |

9.78 |

11.29 |

13.82 |

15.96 |

17.85 |

21.86 |

| 90° |

30 |

|

V

|

4.79 |

6.77 |

9.58 |

11.73 |

13.54 |

16.59 |

19.16 |

21.42 |

26.23 |

| 90° |

35 |

|

V

|

5.59 |

7.90 |

11.17 |

13.69 |

15.80 |

19.35 |

22.35 |

24.99 |

30.60 |

| 90° |

40 |

|

V

|

6.39 |

9.03 |

12.77 |

15.64 |

18.06 |

22.12 |

25.54 |

28.55 |

34.97 |

| 90° |

50 |

|

V

|

7.98 |

11.29 |

15.96 |

19.55 |

22.57 |

27.65 |

31.93 |

35.69 |

43.72 |

| 90° |

60 |

|

|

9.58 |

13.54 |

19.16 |

23.46 |

27.09 |

33.18 |

38.31 |

42.83 |

52.46 |

| 90° |

80 |

|

|

12.77 |

18.06 |

25.54 |

31.38 |

36.12 |

44.24 |

51.08 |

57.11 |

69.94 |

| 90° |

100 |

|

|

15.96 |

22.57 |

31.93 |

39.10 |

45.15 |

55.30 |

63.85 |

71.39 |

87.43 |

| Spray Angle |

Capacity Code |

Thread Size |

Capacity at Pressure |

Capacity at Pressure |

| 1/8" |

1/4" |

0.05

MPa |

0.1

MPa |

0.2

MPa

|

0.3

MPa |

0.4

MPa

|

0.6

MPa |

0.8

MPa |

1.0

MPa |

1.5

MPa |

| 65° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.46 |

0.56 |

0.64 |

0.72 |

0.88 |

| 65° |

02 |

V

|

V

|

0.32 |

0.45 |

0.64 |

0.79 |

0.91 |

1.12 |

1.29 |

1.44 |

1.77 |

| 65° |

2.5 |

V

|

V

|

0.40 |

0.57 |

0.81 |

0.99 |

1.14 |

1.40 |

1.61 |

1.80 |

2.21 |

| 65° |

03 |

V

|

V

|

0.48 |

0.68 |

0.97 |

1.18 |

1.37 |

1.68 |

1.93 |

2.16 |

2.65 |

| 65° |

04 |

V

|

V

|

0.64 |

0.91 |

1.29 |

1.58 |

1.82 |

2.23 |

2.58 |

2.88 |

3.53 |

| 65° |

05 |

V

|

V

|

0.81 |

1.14 |

1.61 |

1.97 |

2.28 |

2.79 |

3.22 |

3.60 |

4.41 |

| 65° |

06 |

V

|

V

|

0.97 |

1.37 |

1.93 |

2.37 |

2.74 |

3.35 |

3.87 |

4.33 |

5.30 |

| 65° |

07 |

V

|

V

|

1.13 |

1.60 |

2.26 |

2.76 |

3.19 |

3.91 |

4.51 |

5.05 |

6.18 |

| 65° |

7.5 |

V

|

V

|

1.21 |

1.71 |

2.42 |

2.96 |

3.42 |

4.19 |

4.81 |

5.41 |

6.62 |

| 65° |

08 |

V

|

V

|

1.29 |

1.82 |

2.58 |

3.16 |

3.65 |

4.47 |

5.16 |

5.77 |

7.06 |

| 65° |

09 |

V

|

V

|

1.45 |

2.05 |

2.90 |

3.55 |

4.10 |

5.03 |

5.80 |

6.49 |

7.95 |

| 65° |

10 |

V

|

V

|

1.61 |

2.28 |

3.22 |

3.95 |

4.56 |

5.58 |

6.45 |

7.21 |

8.83 |

| 65° |

12.5 |

V

|

V

|

2.01 |

2.85 |

4.03 |

4.94 |

5.70 |

6.98 |

8.06 |

9.01 |

11.04 |

| 65° |

15 |

V

|

V

|

2.42 |

3.42 |

4.84 |

5.92 |

6.84 |

8.38 |

9.67 |

10.81 |

13.24 |

| 65° |

20 |

V

|

V

|

3.22 |

4.56 |

6.45 |

7.90 |

9.12 |

11.17 |

12.90 |

14.42 |

17.66 |

| 65° |

25 |

|

V

|

4.03 |

5.70 |

8.06 |

9.87 |

11.40 |

13.96 |

16.12 |

18.02 |

22.07 |

| 65° |

30 |

|

V

|

4.84 |

6.84 |

9.67 |

11.85 |

13.68 |

16.75 |

19.34 |

21.63 |

26.49 |

| 65° |

35 |

|

V

|

5.64 |

7.98 |

11.28 |

13.82 |

15.96 |

19.54 |

22.57 |

25.23 |

30.90 |

| 65° |

40 |

|

V

|

6.45 |

9.12 |

12.90 |

15.79 |

18.24 |

22.34 |

25.79 |

28.83 |

35.52 |

| 65° |

50 |

|

V

|

8.06 |

11.40 |

16.12 |

19.74 |

22.80 |

27.92 |

32.24 |

36.04 |

44.14 |

| 65° |

60 |

|

|

9.67 |

13.68 |

19.34 |

23.69 |

27.36 |

33.50 |

38.69 |

43.25 |

52.97 |

| 65° |

80 |

|

|

12.90 |

18.24 |

25.79 |

31.59 |

36.47 |

44.67 |

51.58 |

57.67 |

70.63 |

| 65° |

100 |

|

|

16.12 |

22.80 |

32.24 |

39.48 |

45.59 |

55.84 |

64.48 |

72.09 |

88.29 |

| 80° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.46 |

0.56 |

0.64 |

0.72 |

0.88 |

| 80° |

02 |

V

|

V

|

0.32 |

0.45 |

0.64 |

0.79 |

0.91 |

1.12 |

1.29 |

1.44 |

1.77 |

| 80° |

2.5 |

V

|

V

|

0.40 |

0.57 |

0.81 |

0.99 |

1.14 |

1.40 |

1.61 |

1.80 |

2.21 |

| 80° |

03 |

V

|

V

|

0.48 |

0.68 |

0.97 |

1.18 |

1.37 |

1.68 |

1.93 |

2.16 |

2.65 |

| 80° |

04 |

V

|

V

|

0.64 |

0.91 |

1.29 |

1.58 |

1.82 |

2.23 |

2.58 |

2.88 |

3.53 |

| 80° |

05 |

V

|

V

|

0.81 |

1.14 |

1.61 |

1.97 |

2.28 |

2.79 |

3.22 |

3.60 |

4.41 |

| 80° |

06 |

V

|

V

|

0.97 |

1.37 |

1.93 |

2.37 |

2.74 |

3.35 |

3.87 |

4.33 |

5.30 |

| 80° |

07 |

V

|

V

|

1.13 |

1.60 |

2.26 |

2.76 |

3.19 |

3.91 |

4.51 |

5.05 |

6.18 |

| 80° |

7.5 |

V

|

V

|

1.21 |

1.71 |

2.42 |

2.96 |

3.42 |

4.19 |

4.81 |

5.41 |

6.62 |

| 80° |

08 |

V

|

V

|

1.29 |

1.82 |

2.58 |

3.16 |

3.65 |

4.47 |

5.16 |

5.77 |

7.06 |

| 80° |

09 |

V

|

V

|

1.45 |

2.05 |

2.90 |

3.55 |

4.10 |

5.03 |

5.80 |

6.49 |

7.95 |

| 80° |

10 |

V

|

V

|

1.61 |

2.28 |

3.22 |

3.95 |

4.56 |

5.58 |

6.45 |

7.21 |

8.83 |

| 80° |

12.5 |

V

|

V

|

2.01 |

2.85 |

4.03 |

4.94 |

5.70 |

6.98 |

8.06 |

9.01 |

11.04 |

| 80° |

15 |

V

|

V

|

2.42 |

3.42 |

4.84 |

5.92 |

6.84 |

8.38 |

9.67 |

10.81 |

13.24 |

| 80° |

20 |

V

|

V

|

3.22 |

4.56 |

6.45 |

7.90 |

9.12 |

11.17 |

12.90 |

14.42 |

17.66 |

| 80° |

25 |

|

V

|

4.03 |

5.70 |

8.06 |

9.87 |

11.40 |

13.96 |

16.12 |

18.02 |

22.07 |

| 80° |

30 |

|

V

|

4.84 |

6.84 |

9.67 |

11.85 |

13.68 |

16.75 |

19.34 |

21.63 |

26.49 |

| 80° |

35 |

|

V

|

5.64 |

7.98 |

11.28 |

13.82 |

15.96 |

19.54 |

22.57 |

25.23 |

30.90 |

| 80° |

40 |

|

V

|

6.45 |

9.12 |

12.90 |

15.79 |

18.24 |

22.34 |

25.79 |

28.83 |

35.52 |

| 80° |

50 |

|

V

|

8.06 |

11.40 |

16.12 |

19.74 |

22.80 |

27.92 |

32.24 |

36.04 |

44.14 |

| 80° |

60 |

|

|

9.67 |

13.68 |

19.34 |

23.69 |

27.36 |

33.50 |

38.69 |

43.25 |

52.97 |

| 80° |

80 |

|

|

12.90 |

18.24 |

25.79 |

31.59 |

36.47 |

44.67 |

51.58 |

57.67 |

70.63 |

| 80° |

100 |

|

|

16.12 |

22.80 |

32.24 |

39.48 |

45.59 |

55.84 |

64.48 |

72.09 |

88.29 |

| 90° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.46 |

0.56 |

0.64 |

0.72 |

0.88 |

| 90° |

02 |

V

|

V

|

0.32 |

0.45 |

0.64 |

0.79 |

0.91 |

1.12 |

1.29 |

1.44 |

1.77 |

| 90° |

2.5 |

V

|

V

|

0.40 |

0.57 |

0.81 |

0.99 |

1.14 |

1.40 |

1.61 |

1.80 |

2.21 |

| 90° |

03 |

V

|

V

|

0.48 |

0.68 |

0.97 |

1.18 |

1.37 |

1.68 |

1.93 |

2.16 |

2.65 |

| 90° |

04 |

V

|

V

|

0.64 |

0.91 |

1.29 |

1.58 |

1.82 |

2.23 |

2.58 |

2.88 |

3.53 |

| 90° |

05 |

V

|

V

|

0.81 |

1.14 |

1.61 |

1.97 |

2.28 |

2.79 |

3.22 |

3.60 |

4.41 |

| 90° |

06 |

V

|

V

|

0.97 |

1.37 |

1.93 |

2.37 |

2.74 |

3.35 |

3.87 |

4.33 |

5.30 |

| 90° |

07 |

V

|

V

|

1.13 |

1.60 |

2.26 |

2.76 |

3.19 |

3.91 |

4.51 |

5.05 |

6.18 |

| 90° |

7.5 |

V

|

V

|

1.21 |

1.71 |

2.42 |

2.96 |

3.42 |

4.19 |

4.81 |

5.41 |

6.62 |

| 90° |

08 |

V

|

V

|

1.29 |

1.82 |

2.58 |

3.16 |

3.65 |

4.47 |

5.16 |

5.77 |

7.06 |

| 90° |

09 |

V

|

V

|

1.45 |

2.05 |

2.90 |

3.55 |

4.10 |

5.03 |

5.80 |

6.49 |

7.95 |

| 90° |

10 |

V

|

V

|

1.61 |

2.28 |

3.22 |

3.95 |

4.56 |

5.58 |

6.45 |

7.21 |

8.83 |

| 90° |

12.5 |

V

|

V

|

2.01 |

2.85 |

4.03 |

4.94 |

5.70 |

6.98 |

8.06 |

9.01 |

11.04 |

| 90° |

15 |

V

|

V

|

2.42 |

3.42 |

4.84 |

5.92 |

6.84 |

8.38 |

9.67 |

10.81 |

13.24 |

| 90° |

20 |

V

|

V

|

3.22 |

4.56 |

6.45 |

7.90 |

9.12 |

11.17 |

12.90 |

14.42 |

17.66 |

| 90° |

25 |

|

V

|

4.03 |

5.70 |

8.06 |

9.87 |

11.40 |

13.96 |

16.12 |

18.02 |

22.07 |

| 90° |

30 |

|

V

|

4.84 |

6.84 |

9.67 |

11.85 |

13.68 |

16.75 |

19.34 |

21.63 |

26.49 |

| 90° |

35 |

|

V

|

5.64 |

7.98 |

11.28 |

13.82 |

15.96 |

19.54 |

22.57 |

25.23 |

30.90 |

| 90° |

40 |

|

V

|

6.45 |

9.12 |

12.90 |

15.79 |

18.24 |

22.34 |

25.79 |

28.83 |

35.52 |

| 90° |

50 |

|

V

|

8.06 |

11.40 |

16.12 |

19.74 |

22.80 |

27.92 |

32.24 |

36.04 |

44.14 |

| 90° |

60 |

|

|

9.67 |

13.68 |

19.34 |

23.69 |

27.36 |

33.50 |

38.69 |

43.25 |

52.97 |

| 90° |

80 |

|

|

12.90 |

18.24 |

25.79 |

31.59 |

36.47 |

44.67 |

51.58 |

57.67 |

70.63 |

| 90° |

100 |

|

|

16.12 |

22.80 |

32.24 |

39.48 |

45.59 |

55.84 |

64.48 |

72.09 |

88.29 |

| Spray Angle |

Capacity Code |

Thread Size |

Capacity at Pressure |

Capacity at Pressure |

| 1/8" |

1/4" |

0.5

bar

|

1.0

bar |

2.0

bar

|

3.0

bar |

4.0

bar

|

6.0

bar |

8.0

bar |

10.0

bar |

15.0

bar |

| 65° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.46 |

0.56 |

0.64 |

0.72 |

0.88 |

| 65° |

02 |

V

|

V

|

0.32 |

0.46 |

0.64 |

0.79 |

0.91 |

1.12 |

1.29 |

1.44 |

1.77 |

| 65° |

2.5 |

V

|

V

|

0.40 |

0.57 |

0.81 |

0.99 |

1.14 |

1.40 |

1.61 |

1.80 |

2.21 |

| 65° |

03 |

V

|

V

|

0.48 |

0.68 |

0.97 |

1.18 |

1.37 |

1.68 |

1.93 |

2.16 |

2.65 |

| 65° |

04 |

V

|

V

|

0.64 |

0.91 |

1.29 |

1.58 |

1.82 |

2.23 |

2.58 |

2.88 |

3.53 |

| 65° |

05 |

V

|

V

|

0.81 |

1.14 |

1.61 |

1.97 |

2.28 |

2.79 |

3.22 |

3.60 |

4.41 |

| 65° |

06 |

V

|

V

|

0.97 |

1.37 |

1.93 |

2.37 |

2.74 |

3.35 |

3.87 |

4.33 |

5.30 |

| 65° |

07 |

V

|

V

|

1.13 |

1.60 |

2.26 |

2.76 |

3.19 |

3.91 |

4.51 |

5.05 |

6.18 |

| 65° |

7.5 |

V

|

V

|

1.21 |

1.71 |

2.42 |

2.96 |

3.42 |

4.19 |

4.84 |

5.41 |

6.62 |

| 65° |

08 |

V

|

V

|

1.29 |

1.82 |

2.58 |

3.16 |

3.65 |

4.47 |

5.16 |

5.77 |

7.06 |

| 65° |

09 |

V

|

V

|

1.45 |

2.05 |

2.90 |

3.55 |

4.10 |

5.03 |

5.80 |

6.49 |

7.95 |

| 65° |

10 |

V

|

V

|

1.61 |

2.28 |

3.22 |

3.95 |

4.56 |

5.58 |

6.45 |

7.21 |

8.83 |

| 65° |

12.5 |

V

|

V

|

2.01 |

2.85 |

4.03 |

4.94 |

5.70 |

6.98 |

8.06 |

9.01 |

11.04 |

| 65° |

15 |

V

|

V

|

2.42 |

3.42 |

4.84 |

5.92 |

6.84 |

8.38 |

9.67 |

10.81 |

13.24 |

| 65° |

20 |

V

|

V

|

3.22 |

4.56 |

6.45 |

7.90 |

9.12 |

11.19 |

12.90 |

14.42 |

17.66 |

| 65° |

25 |

|

V

|

4.03 |

5.70 |

8.06 |

9.87 |

11.40 |

13.96 |

16.12 |

18.02 |

22.07 |

| 65° |

30 |

|

V

|

4.84 |

6.84 |

9.67 |

11.85 |

13.68 |

16.75 |

19.34 |

21.63 |

26.49 |

| 65° |

35 |

|

V

|

5.64 |

7.98 |

11.28 |

13.82 |

15.96 |

19.54 |

22.57 |

25.23 |

30.90 |

| 65° |

40 |

|

V

|

6.45 |

9.12 |

12.90 |

15.79 |

18.24 |

22.34 |

25.75 |

28.83 |

35.32 |

| 65° |

50 |

|

V

|

8.06 |

11.40 |

16.12 |

19.74 |

22.80 |

27.92 |

32.24 |

36.06 |

44.14 |

| 65° |

60 |

|

|

9.67 |

13.68 |

19.23 |

23.69 |

27.36 |

33.50 |

38.69 |

43.25 |

52.97 |

| 65° |

80 |

|

|

12.90 |

18.24 |

25.79 |

31.59 |

36.47 |

44.67 |

51.58 |

57.67 |

70.63 |

| 65° |

100 |

|

|

16.12 |

22.80 |

32.24 |

39.48 |

45.59 |

55.84 |

64.48 |

72.09 |

88.29 |

| 80° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.46 |

0.56 |

0.64 |

0.72 |

0.88 |

| 80° |

02 |

V

|

V

|

0.32 |

0.46 |

0.64 |

0.79 |

0.91 |

1.12 |

1.29 |

1.44 |

1.77 |

| 80° |

2.5 |

V

|

V

|

0.40 |

0.57 |

0.81 |

0.99 |

1.14 |

1.40 |

1.61 |

1.80 |

2.21 |

| 80° |

03 |

V

|

V

|

0.48 |

0.68 |

0.97 |

1.18 |

1.37 |

1.68 |

1.93 |

2.16 |

2.65 |

| 80° |

04 |

V

|

V

|

0.64 |

0.91 |

1.29 |

1.58 |

1.82 |

2.23 |

2.58 |

2.88 |

3.53 |

| 80° |

05 |

V

|

V

|

0.81 |

1.14 |

1.61 |

1.97 |

2.28 |

2.79 |

3.22 |

3.60 |

4.41 |

| 80° |

06 |

V

|

V

|

0.97 |

1.37 |

1.93 |

2.37 |

2.74 |

3.35 |

3.87 |

4.33 |

5.30 |

| 80° |

07 |

V

|

V

|

1.13 |

1.60 |

2.26 |

2.76 |

3.19 |

3.91 |

4.51 |

5.05 |

6.18 |

| 80° |

7.5 |

V

|

V

|

1.21 |

1.71 |

2.42 |

2.96 |

3.42 |

4.19 |

4.84 |

5.41 |

6.62 |

| 80° |

08 |

V

|

V

|

1.29 |

1.82 |

2.58 |

3.16 |

3.65 |

4.47 |

5.16 |

5.77 |

7.06 |

| 80° |

09 |

V

|

V

|

1.45 |

2.05 |

2.90 |

3.55 |

4.10 |

5.03 |

5.80 |

6.49 |

7.95 |

| 80° |

10 |

V

|

V

|

1.61 |

2.28 |

3.22 |

3.95 |

4.56 |

5.58 |

6.45 |

7.21 |

8.83 |

| 80° |

12.5 |

V

|

V

|

2.01 |

2.85 |

4.03 |

4.94 |

5.70 |

6.98 |

8.06 |

9.01 |

11.04 |

| 80° |

15 |

V

|

V

|

2.42 |

3.42 |

4.84 |

5.92 |

6.84 |

8.38 |

9.67 |

10.81 |

13.24 |

| 80° |

20 |

V

|

V

|

3.22 |

4.56 |

6.45 |

7.90 |

9.12 |

11.19 |

12.90 |

14.42 |

17.66 |

| 80° |

25 |

|

V

|

4.03 |

5.70 |

8.06 |

9.87 |

11.40 |

13.96 |

16.12 |

18.02 |

22.07 |

| 80° |

30 |

|

V

|

4.84 |

6.84 |

9.67 |

11.85 |

13.68 |

16.75 |

19.34 |

21.63 |

26.49 |

| 80° |

35 |

|

V

|

5.64 |

7.98 |

11.28 |

13.82 |

15.96 |

19.54 |

22.57 |

25.23 |

30.90 |

| 80° |

40 |

|

V

|

6.45 |

9.12 |

12.90 |

15.79 |

18.24 |

22.34 |

25.75 |

28.83 |

35.32 |

| 80° |

50 |

|

V

|

8.06 |

11.40 |

16.12 |

19.74 |

22.80 |

27.92 |

32.24 |

36.06 |

44.14 |

| 80° |

60 |

|

|

9.67 |

13.68 |

19.23 |

23.69 |

27.36 |

33.50 |

38.69 |

43.25 |

52.97 |

| 80° |

80 |

|

|

12.90 |

18.24 |

25.79 |

31.59 |

36.47 |

44.67 |

51.58 |

57.67 |

70.63 |

| 80° |

100 |

|

|

16.12 |

22.80 |

32.24 |

39.48 |

45.59 |

55.84 |

64.48 |

72.09 |

88.29 |

| 90° |

01 |

V

|

V

|

0.16 |

0.23 |

0.32 |

0.39 |

0.46 |

0.56 |

0.64 |

0.72 |

0.88 |

| 90° |

02 |

V

|

V

|

0.32 |

0.46 |

0.64 |

0.79 |

0.91 |

1.12 |

1.29 |

1.44 |

1.77 |

| 90° |

2.5 |

V

|

V

|

0.40 |

0.57 |

0.81 |

0.99 |

1.14 |

1.40 |

1.61 |

1.80 |

2.21 |

| 90° |

03 |

V

|

V

|

0.48 |

0.68 |

0.97 |

1.18 |

1.37 |

1.68 |

1.93 |

2.16 |

2.65 |

| 90° |

04 |

V

|

V

|

0.64 |

0.91 |

1.29 |

1.58 |

1.82 |

2.23 |

2.58 |

2.88 |

3.53 |

| 90° |

05 |

V

|

V

|

0.81 |

1.14 |

1.61 |

1.97 |

2.28 |

2.79 |

3.22 |

3.60 |

4.41 |

| 90° |

06 |

V

|

V

|

0.97 |

1.37 |

1.93 |

2.37 |

2.74 |

3.35 |

3.87 |

4.33 |

5.30 |

| 90° |

07 |

V

|

V

|

1.13 |

1.60 |

2.26 |

2.76 |

3.19 |

3.91 |

4.51 |

5.05 |

6.18 |

| 90° |

7.5 |

V

|

V

|

1.21 |

1.71 |

2.42 |

2.96 |

3.42 |

4.19 |

4.84 |

5.41 |

6.62 |

| 90° |

08 |

V

|

V

|

1.29 |

1.82 |

2.58 |

3.16 |

3.65 |

4.47 |

5.16 |

5.77 |

7.06 |

| 90° |

09 |

V

|

V

|

1.45 |

2.05 |

2.90 |

3.55 |

4.10 |

5.03 |

5.80 |

6.49 |

7.95 |

| 90° |

10 |

V

|

V

|

1.61 |

2.28 |

3.22 |

3.95 |

4.56 |

5.58 |

6.45 |

7.21 |

8.83 |

| 90° |

12.5 |

V

|

V

|

2.01 |

2.85 |

4.03 |

4.94 |

5.70 |

6.98 |

8.06 |

9.01 |

11.04 |

| 90° |

15 |

V

|

V

|

2.42 |

3.42 |

4.84 |

5.92 |

6.84 |

8.38 |

9.67 |

10.81 |

13.24 |

| 90° |

20 |

V

|

V

|

3.22 |

4.56 |

6.45 |

7.90 |

9.12 |

11.19 |

12.90 |

14.42 |

17.66 |

| 90° |

25 |

|

V

|

4.03 |

5.70 |

8.06 |

9.87 |

11.40 |

13.96 |

16.12 |

18.02 |

22.07 |

| 90° |

30 |

|

V

|

4.84 |

6.84 |

9.67 |

11.85 |

13.68 |

16.75 |

19.34 |

21.63 |

26.49 |

| 90° |

35 |

|

V

|

5.64 |

7.98 |

11.28 |

13.82 |

15.96 |

19.54 |

22.57 |

25.23 |

30.90 |

| 90° |

40 |

|

V

|

6.45 |

9.12 |

12.90 |

15.79 |

18.24 |

22.34 |

25.75 |

28.83 |

35.32 |

| 90° |

50 |

|

V

|

8.06 |

11.40 |

16.12 |

19.74 |

22.80 |

27.92 |

32.24 |

36.06 |

44.14 |

| 90° |

60 |

|

|

9.67 |

13.68 |

19.23 |

23.69 |

27.36 |

33.50 |

38.69 |

43.25 |

52.97 |

| 90° |

80 |

|

|

12.90 |

18.24 |

25.79 |

31.59 |

36.47 |

44.67 |

51.58 |

57.67 |

70.63 |

| 90° |

100 |

|

|

16.12 |

22.80 |

32.24 |

39.48 |

45.59 |

55.84 |

64.48 |

72.09 |

88.29 |

| Spray Angle |

Capacity Code |

Thread Size |

Capacity at Pressure |

Capacity at Pressure |

| 1/8" |

1/4" |

7

psi |

10

psi |

28

psi

|

40

psi |

60

psi

|

80

psi |

100

psi |

150

psi |

200

psi |

| 65° |

01 |

V

|

V

|

0.04 |

0.05 |

0.08 |

0.10 |

0.12 |

0.14 |

0.16 |

0.19 |

0.22 |

| 65° |

02 |

V

|

V

|

0.08 |

0.10 |

0.17 |

0.20 |

0.24 |

0.28 |

0.32 |

0.39 |

0.45 |

| 65° |

2.5 |

V

|

V

|

0.10 |

0.13 |

0.21 |

0.25 |

0.31 |

0.35 |

0.40 |

0.48 |

0.56 |

| 65° |

03 |

V

|

V

|

0.13 |

0.15 |

0.25 |

0.30 |

0.37 |

0.42 |

0.47 |

0.58 |

0.67 |

| 65° |

04 |

V

|

V

|

0.17 |

0.20 |

0.33 |

0.40 |

0.49 |

0.57 |

0.63 |

0.77 |

0.89 |

| 65° |

05 |

V

|

V

|

0.21 |

0.25 |

0.42 |

0.50 |

0.61 |

0.71 |

0.79 |

0.97 |

1.12 |

| 65° |

06 |

V

|

V

|

0.25 |

0.30 |

0.50 |

0.60 |

0.73 |

0.85 |

0.95 |

1.16 |

1.34 |

| 65° |

07 |

V

|

V

|

0.29 |

0.35 |

0.59 |

0.70 |

0.86 |

0.99 |

1.11 |

1.36 |

1.57 |

| 65° |

7.5 |

V

|

V

|

0.31 |

0.38 |

0.63 |

0.75 |

0.92 |

1.06 |

1.19 |

1.45 |

1.68 |

| 65° |

08 |

V

|

V

|

0.33 |

0.40 |

0.67 |

0.80 |

0.98 |

1.13 |

1.27 |

1.55 |

1.79 |

| 65° |

09 |

V

|

V

|

0.38 |

0.45 |

0.75 |

0.90 |

1.10 |

1.27 |

1.42 |

1.74 |

2.01 |

| 65° |

10 |

V

|

V

|

0.42 |

0.50 |

0.84 |

1.00 |

1.22 |

1.41 |

1.58 |

1.94 |

2.24 |

| 65° |

12.5 |

V

|

V

|

0.52 |

0.63 |

1.05 |

1.25 |

1.53 |

1.77 |

1.98 |

2.42 |

2.80 |

| 65° |

15 |

V

|

V

|

0.63 |

0.75 |

1.26 |

1.50 |

1.84 |

2.12 |

2.37 |

2.90 |

3.35 |

| 65° |

20 |

V

|

V

|

0.84 |

1.00 |

1.67 |

2.00 |

2.45 |

2.83 |

3.16 |

3.87 |

4.47 |

| 65° |

25 |

|

V

|

1.05 |

1.25 |

2.09 |

2.50 |

3.06 |

3.54 |

3.95 |

4.84 |

5.59 |

| 65° |

30 |

|

V

|

1.26 |

1.50 |

2.51 |

3.00 |

3.67 |

4.24 |

4.74 |

5.81 |

6.71 |

| 65° |

35 |

|

V

|

1.46 |

1.75 |

2.93 |

3.50 |

4.29 |

4.95 |

5.53 |

6.78 |

7.83 |

| 65° |

40 |

|

V

|

1.67 |

2.00 |

3.35 |

4.00 |

4.90 |

5.66 |

6.33 |

7.75 |

8.94 |

| 65° |

50 |

|

V

|

2.09 |

2.50 |

4.18 |

5.00 |

6.12 |

7.07 |

7.91 |

9.68 |

11.18 |

| 65° |

60 |

|

|

2.51 |

3.00 |

5.02 |

6.00 |

7.35 |

8.49 |

9.49 |

11.62 |

13.42 |

| 65° |

80 |

|

|

3.35 |

4.00 |

6.69 |

8.00 |

9.80 |

11.31 |

12.65 |

15.49 |

17.89 |

| 65° |

100 |

|

|

4.18 |

5.00 |

8.37 |

10.00 |

12.25 |

14.14 |

15.81 |

19.37 |

22.36 |

| 80° |

01 |

V

|

V

|

0.04 |

0.05 |

0.08 |

0.10 |

0.12 |

0.14 |

0.16 |

0.19 |

0.22 |

| 80° |

02 |

V

|

V

|

0.08 |

0.10 |

0.17 |

0.20 |

0.24 |

0.28 |

0.32 |

0.39 |

0.45 |

| 80° |

2.5 |

V

|

V

|

0.10 |

0.13 |

0.21 |

0.25 |

0.31 |

0.35 |

0.40 |

0.48 |

0.56 |

| 80° |

03 |

V

|

V

|

0.13 |

0.15 |

0.25 |

0.30 |

0.37 |

0.42 |

0.47 |

0.58 |

0.67 |

| 80° |

04 |

V

|

V

|

0.17 |

0.20 |

0.33 |

0.40 |

0.49 |

0.57 |

0.63 |

0.77 |

0.89 |

| 80° |

05 |

V

|

V

|

0.21 |

0.25 |

0.42 |

0.50 |

0.61 |

0.71 |

0.79 |

0.97 |

1.12 |

| 80° |

06 |

V

|

V

|

0.25 |

0.30 |

0.50 |

0.60 |

0.73 |

0.85 |

0.95 |

1.16 |

1.34 |

| 80° |

07 |

V

|

V

|

0.29 |

0.35 |

0.59 |

0.70 |

0.86 |

0.99 |

1.11 |

1.36 |

1.57 |

| 80° |

7.5 |

V

|

V

|

0.31 |

0.38 |

0.63 |

0.75 |

0.92 |

1.06 |

1.19 |

1.45 |

1.68 |

| 80° |

08 |

V

|

V

|

0.33 |

0.40 |

0.67 |

0.80 |

0.98 |

1.13 |

1.27 |

1.55 |

1.79 |

| 80° |

09 |

V

|

V

|

0.38 |

0.45 |

0.75 |

0.90 |

1.10 |

1.27 |

1.42 |

1.74 |

2.01 |

| 80° |

10 |

V

|

V

|

0.42 |

0.50 |

0.84 |

1.00 |

1.22 |

1.41 |

1.58 |

1.94 |

2.24 |

| 80° |

12.5 |

V

|

V

|

0.52 |

0.63 |

1.05 |

1.25 |

1.53 |

1.77 |

1.98 |

2.42 |

2.80 |

| 80° |

15 |

V

|

V

|

0.63 |

0.75 |

1.26 |

1.50 |

1.84 |

2.12 |

2.37 |

2.90 |

3.35 |

| 80° |

20 |

V

|

V

|

0.84 |

1.00 |

1.67 |

2.00 |

2.45 |

2.83 |

3.16 |

3.87 |

4.47 |

| 80° |

25 |

V

|

V

|

1.05 |

1.25 |

2.09 |

2.50 |

3.06 |

3.54 |

3.95 |

4.84 |

5.59 |

| 80° |

30 |

|

V

|

1.26 |

1.50 |

2.51 |

3.00 |

3.67 |

4.24 |

4.74 |

5.81 |

6.71 |

| 80° |

35 |

|

V

|

1.46 |

1.75 |

2.93 |

3.50 |

4.29 |

4.95 |

5.53 |

6.78 |

7.83 |

| 80° |

40 |

|

V

|

1.67 |

2.00 |

3.35 |

4.00 |

4.90 |

5.66 |

6.33 |

7.75 |

8.94 |

| 80° |

50 |

|

V

|

2.09 |

2.50 |

4.18 |

5.00 |

6.12 |

7.07 |

7.91 |

9.68 |

11.18 |

| 80° |

60 |

|

|

2.51 |

3.00 |

5.02 |

6.00 |

7.35 |

8.49 |

9.49 |

11.62 |

13.42 |

| 80° |

80 |

|

|

3.35 |

4.00 |

6.69 |

8.00 |

9.80 |

11.31 |

12.65 |

15.49 |

17.89 |

| 80° |

100 |

|

|

4.18 |

5.00 |

8.37 |

10.00 |

12.25 |

14.14 |

15.81 |

19.37 |

22.36 |

| 90° |

01 |

V

|

V

|

0.04 |

0.05 |

0.08 |

0.10 |

0.12 |

0.14 |

0.16 |

0.19 |

0.22 |

| 90° |

02 |

V

|

V

|

0.08 |

0.10 |

0.17 |

0.20 |

0.24 |

0.28 |

0.32 |

0.39 |

0.45 |

| 90° |

2.5 |

V

|

V

|

0.10 |

0.13 |

0.21 |

0.25 |

0.31 |

0.35 |

0.40 |

0.48 |

0.56 |

| 90° |

03 |

V

|

V

|

0.13 |

0.15 |

0.25 |

0.30 |

0.37 |

0.42 |

0.47 |

0.58 |

0.67 |

| 90° |

04 |

V

|

V

|

0.17 |

0.20 |

0.33 |

0.40 |

0.49 |

0.57 |

0.63 |

0.77 |

0.89 |

| 90° |

05 |

V

|

V

|

0.21 |

0.25 |

0.42 |

0.50 |

0.61 |

0.71 |

0.79 |

0.97 |

1.12 |

| 90° |

06 |

V

|

V

|

0.25 |

0.30 |

0.50 |

0.60 |

0.73 |

0.85 |

0.95 |

1.16 |

1.34 |

| 90° |

07 |

V

|

V

|

0.29 |

0.35 |

0.59 |

0.70 |

0.86 |

0.99 |

1.11 |

1.36 |

1.57 |

| 90° |

7.5 |

V

|

V

|

0.31 |

0.38 |

0.63 |

0.75 |

0.92 |

1.06 |

1.19 |

1.45 |

1.68 |

| 90° |

08 |

V

|

V

|

0.33 |

0.40 |

0.67 |

0.80 |

0.98 |

1.13 |

1.27 |

1.55 |

1.79 |

| 90° |

09 |

V

|

V

|

0.38 |

0.45 |

0.75 |

0.90 |

1.10 |

1.27 |

1.42 |

1.74 |

2.01 |

| 90° |

10 |

V

|

V

|

0.42 |

0.50 |

0.84 |

1.00 |

1.22 |

1.41 |

1.58 |

1.94 |

2.24 |

| 90° |

12.5 |

V

|

V

|

0.52 |

0.63 |

1.05 |

1.25 |

1.53 |

1.77 |

1.98 |

2.42 |

2.80 |

| 90° |

15 |

V

|

V

|

0.63 |

0.75 |

1.26 |

1.50 |

1.84 |

2.12 |

2.37 |

2.90 |

3.35 |

| 90° |

20 |

V

|

V

|

0.84 |

1.00 |

1.67 |

2.00 |

2.45 |

2.83 |

3.16 |

3.87 |

4.47 |

| 90° |

25 |

|

V

|

1.05 |

1.25 |

2.09 |

2.50 |

3.06 |

3.54 |

3.95 |

4.84 |

5.59 |

| 90° |

30 |

|

V

|

1.26 |

1.50 |

2.51 |

3.00 |

3.67 |

4.24 |

4.74 |

5.81 |

6.71 |

| 90° |

35 |

|

V

|

1.46 |

1.75 |

2.93 |

3.50 |

4.29 |

4.95 |

5.53 |

6.78 |

7.83 |

| 90° |

40 |

|

V

|

1.67 |

2.00 |

3.35 |

4.00 |

4.90 |

5.66 |

6.33 |

7.75 |

8.94 |

| 90° |

50 |

|

V

|

2.09 |

2.50 |

4.18 |

5.00 |

6.12 |

7.07 |

7.91 |

9.68 |

11.18 |

| 90° |

60 |

|

|

2.51 |

3.00 |

5.02 |

6.00 |

7.35 |

8.49 |

9.49 |

11.62 |

13.42 |

| 90° |

80 |

|

|

3.35 |

4.00 |

6.69 |

8.00 |

9.80 |

11.31 |

12.65 |

15.49 |

17.89 |

| 90° |

100 |

|

|

4.18 |

5.00 |

8.37 |

10.00 |

12.25 |

14.14 |

15.81 |

19.37 |

22.36 |

- * Standard Pressure: Column in red.

- * This product for spray angle 0°, 15°, 25°, 40°, 50°, 100° and 110° is able to be made to order.

- * For mobile friendly, only 3 column with 3 kinds of pressure will be displayed. For more pressure data, please check the chart on PC or laptop.

Material

Material Options

Material Guarantees

Metal

We take high quality smithing metal to produce solid and durable nozzles by detail turning.

Plastic

We promise never using recycled materials.

High Quality

All material is purchased from world top providers.

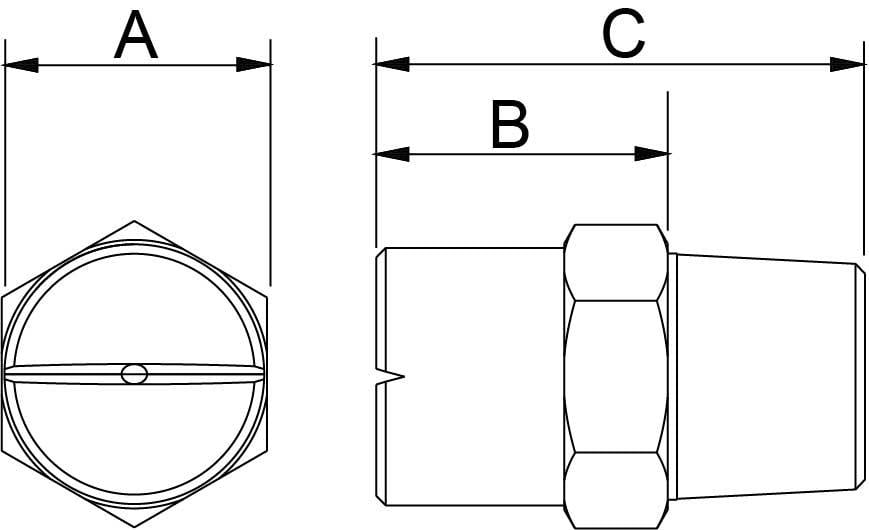

Product Size

Thread

(BSPT)

|

Size (mm)

|

Weight (g)

|

| A

|

B

|

C

|

1/8"Male

|

11.9

|

10.4 |

19.4 |

|

| 1/4"Male |

13.6 |

13.4 |

25 |

2.5 |

* 1/8" Male product was a few left in stock and no longer produced. Please choose

VH to get the same the product with the same spec.

Installation

Easy installing with 2 simple steps !

Step 1

Drill correspon-ding female threads on your pipe.

Step 2

For better leakproof-ness, please use Teflon seal tape on nozzle thread.

Aim the thread of nozzle at the female thread. Tighten the nozzle clockwise.

Products you may also like